CLT production line for Binderholz in Burgbernheim

The company Binder has invested in a new industrial production plant of BBS XL large format cross-laminated timber panels for its CLT plant in Burgbernheim/Germany. The line at Binderholz is currently ramping up and will shortly be supplying the market with high quality BBS cross laminated timber panels. Ledinek was entrusted with the core of the CLT BBS production plant. The production line was delivered, from lamella planing to finished pressed BBS XL cross-laminated timber panels, by company Ledinek.

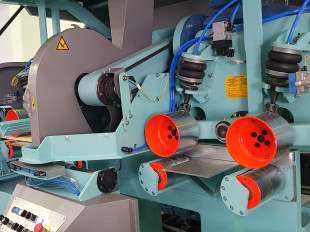

The 2 newly developed Z-Presses are also being used for the first time to glue the lamellae together using hot melt adhesive. Multiple widths or single-layer panels are produced from laminations glued on the narrow side. Such pre-glued single-layer panels are unavoidable for the progressive and high-performance, state of the art, CLT production and thereby initiate a new area and quality in the CLT production.

Company: Binderholz

www: Binderholz BBS XL

Location: Burgbernheim / Deutschland

Wood species: Spurce

Production capacity: over 100.000 m³ / Year

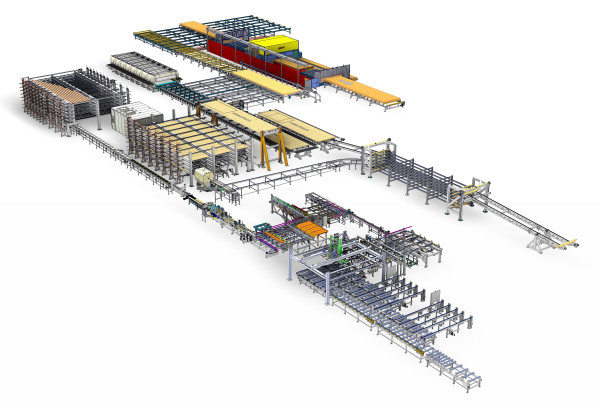

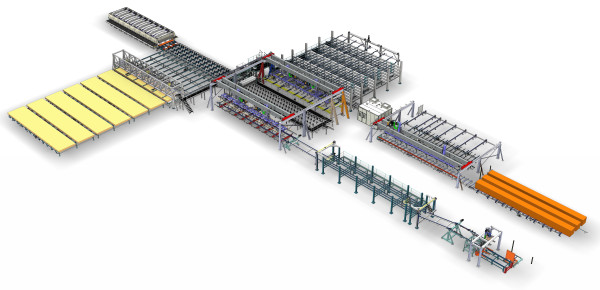

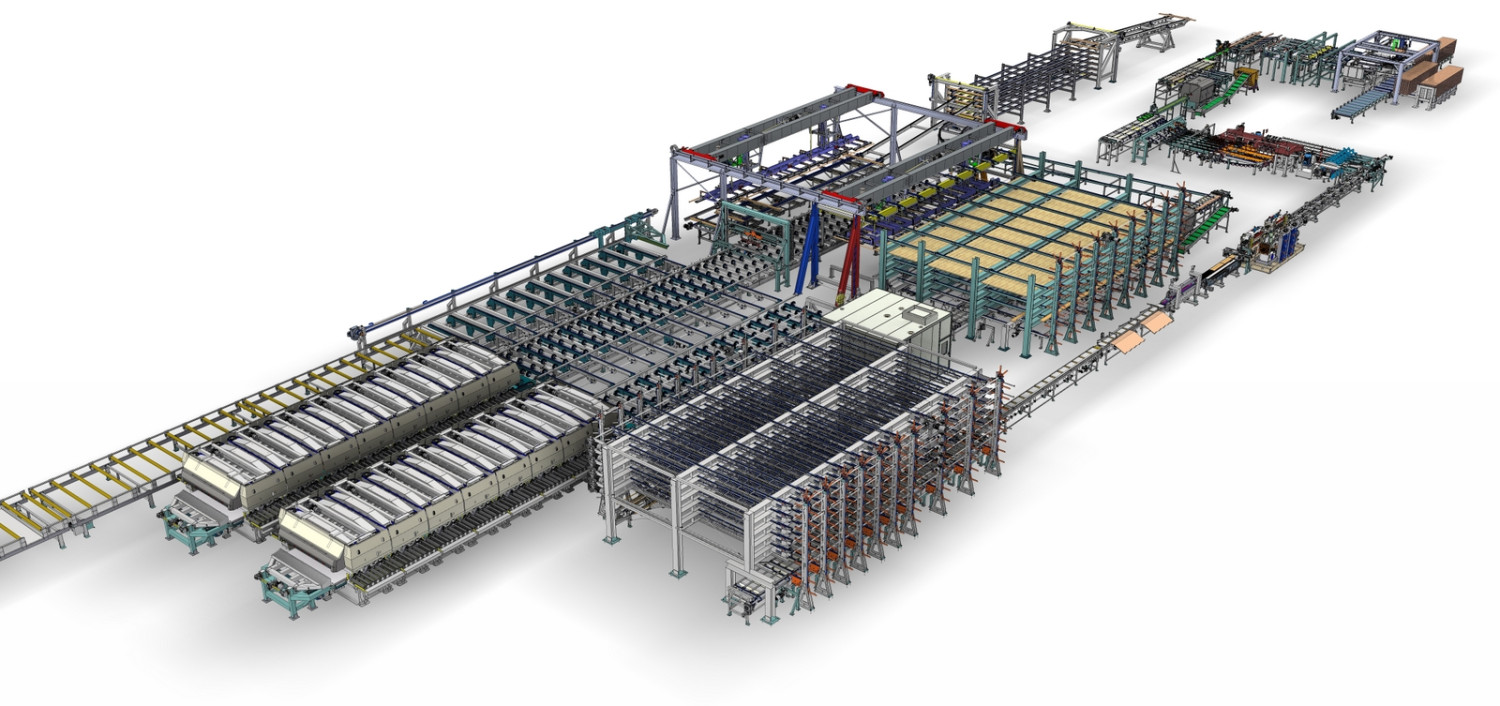

Layout is symbolic

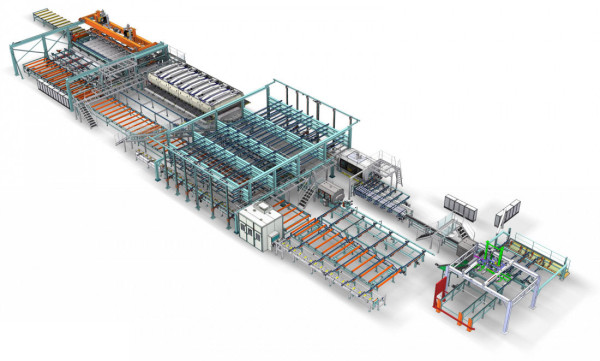

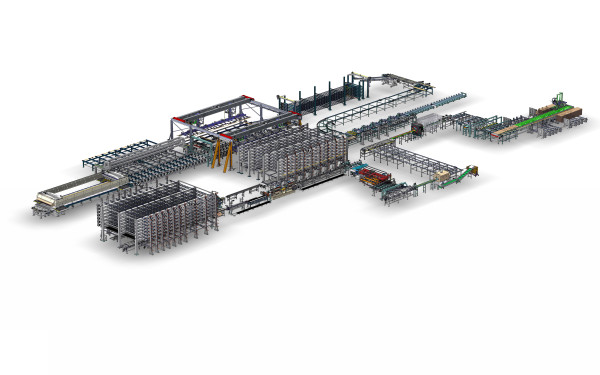

Turnkey CLT production

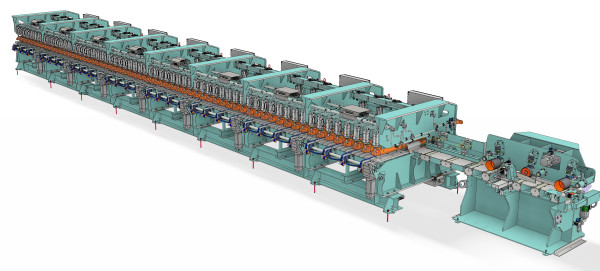

1. Ledinek planer for laminations; high speed

and perfect finish

2. Z-Press Hot-melt edge gluing for fast

assembly bonding of solid wood laminations

3. Multi tray storage for longitudinal

laminations – bonded to single layer panels

4. Planer for laminations used for the cross

layer; high speed and perfect finish

5. Z-Press Hot-melt edge gluing for side boards

and narrow laminations

6. Ledinek cross-cut saw for cross laminations

up to 320 mm width

7. In-feed to Multi tray storage for cross

laminations

8. Multi tray storage (10 trays) for cross

laminations

9. External infeed system for cross layers (single

layer panels or different timber species)

10. Vacuum layer assembly unit for Longitudinal Layers

11. Vacuum layer assembly unit for Cross Layers

12. PUR (1K Polyurethane adhesive) surface

gluing

13. Solid

fast movable PE coated aluminium table for CLT panel assembly up to 120 m/min

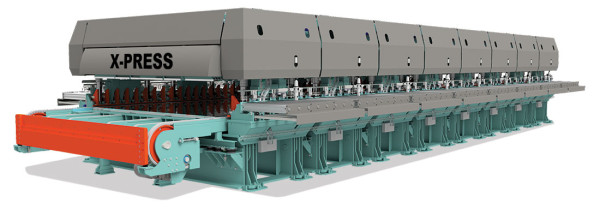

14. First X-PRESS 16 - cross laminated timber press with up to 0,8 N/mm²

pressure

15. Second X-PRESS 16 m x 3,5 m x 0,36 m

16. Cross CLT panel push off unit with outfeed roll and chain conveyors

Facts

- Production capacity over 100.000 m³/year

- Fast PUR (1K Polyurethane adhesive) for surface gluing with cold setting

- Very short pressing cycle

- High flexibility of the CLT production process