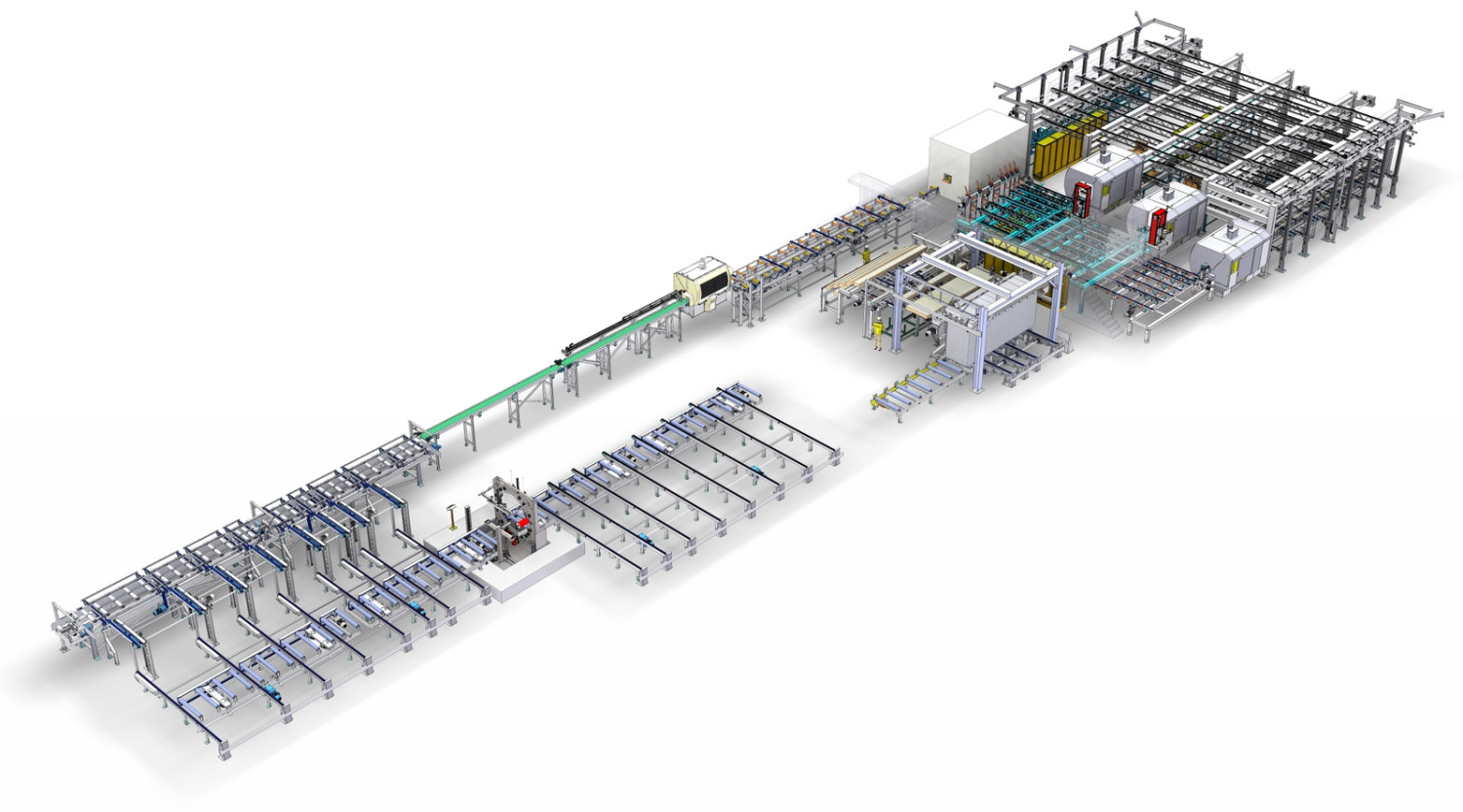

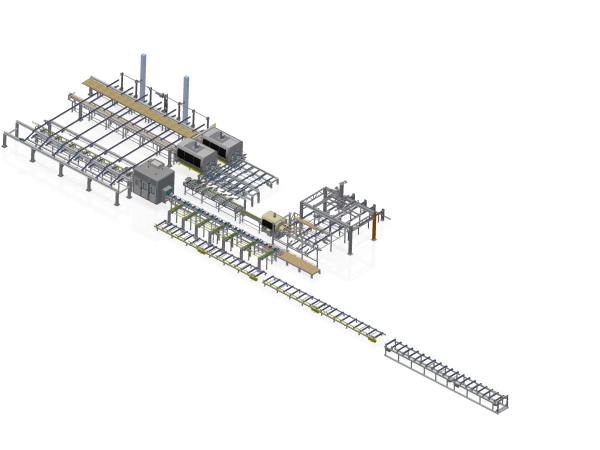

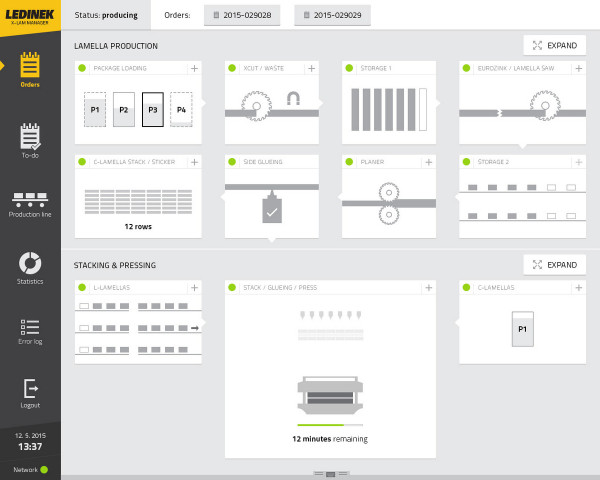

Solid finger jointed constructional timber line

Since August 2015 in the new plant in Tragwein by Handlos solid finger jointed timber (KVH) has been produced. Decisive for the choice of supplier Ledinek was the ability to hand over a complete plant turnkey. As a result, there were no interfaces between different companies.

"In order to avoid interfaces, we wanted one supplier and a responsible person for this project who was our contact person right from the start. The machines, tools and adhesive supplier were organized by Ledinek," explains Mr. Herbert Handlos, Managing Director of the company of the same name. For him, it was also important to keep the investment as low as possible. Therefore, the system was installed in an existing 1800 m² hall.

3 x 6 joints per minute

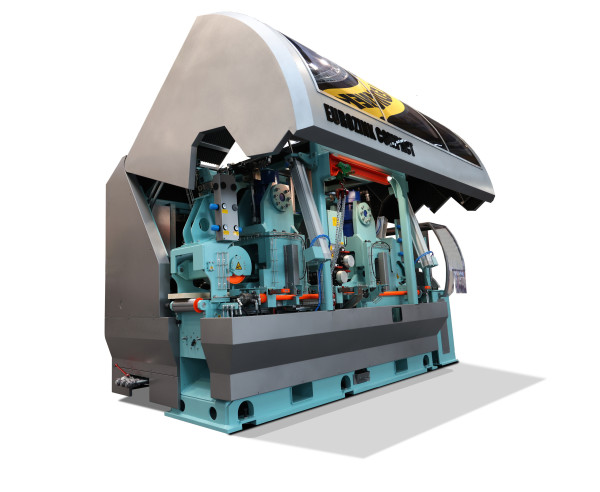

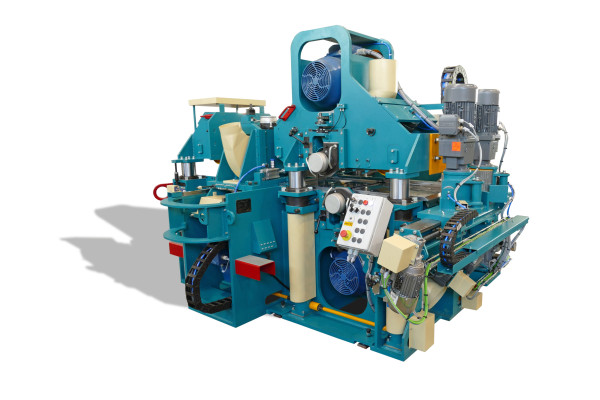

The line is equipped with two (three) Eurozink Compact-6 finger-jointing machines as well as two X-Cut defecting saws and one Europlan for final planing. All preparations have already been made for a third finger jointing machine. The timber sections are pressed together with up to 40 t, which produces maximum cross sections of 400 cm². The largest dimensions are 12 cm times 32 cm up to 16 cm times 24 cm. Mainly they want to offer standard dimensions. The production should be kept as simple as possible.

Case:

- production of standard cross sections

- high production volume

- minimal investment

- reduction of heavy labour

- automated control

Key components of the solution:

- Vacuum de-stacker

- Grading and marking station

- X-CUT cross cut saw for defects

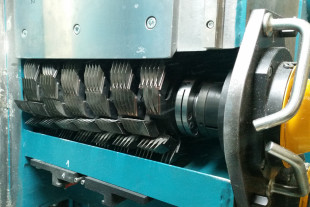

- EUROZINK COMPACT finger jointing machines - 2 pieces (now already 3 pieces)

- Film tray storage after finger jointing

- EUROPLAN beam planer with chamfering units

- X-CUT for precise length cutting

- Stacker

- Foil wrapping