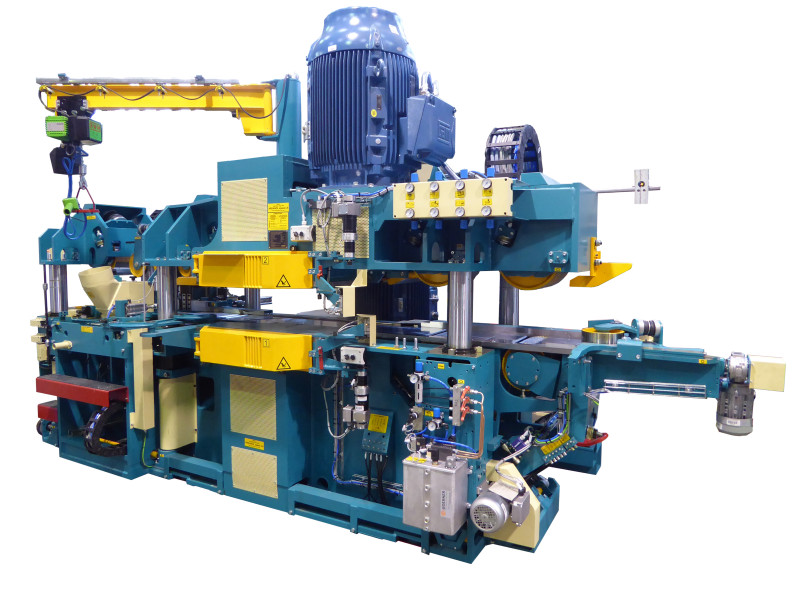

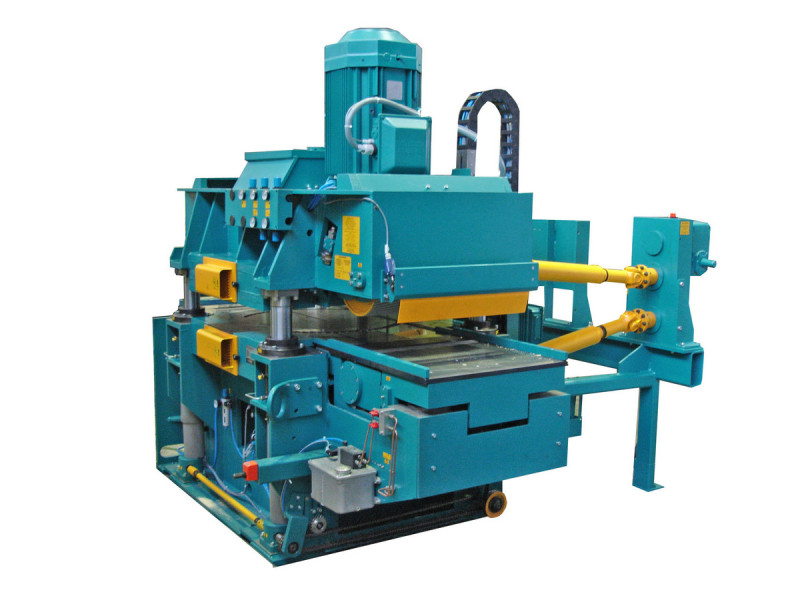

Rotoles S calibrating milling planers with roller feed

Superb accuracy for boards and best results at delamination test, at any speed.

ROTOLES S calibrating milling machines are the best choice for calibration of boards and laminations before gluing.

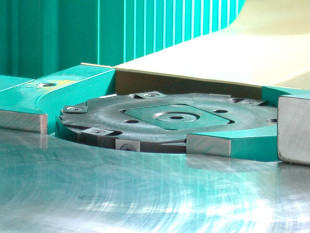

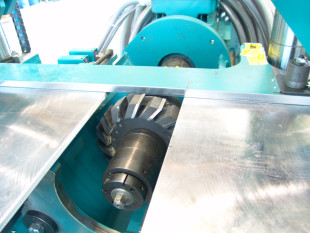

Face milling method offers improved quality of machining compared to conventional planing:

- No planer snipe

- No planer marks

- Higher calibration precision at high machining speed

- Perfect machining of wood knots and their edges or any damaged areas

- No deformation of cell structure, therefore smooth and open pore surface

These features present significant advantages for subsequent processing:

- Lower consumption of glue for glulam beams, panels and parquet

- Uniform glue bond - consistent delamination test results

- Better penetration of varnish, oil or wax into the wood structure

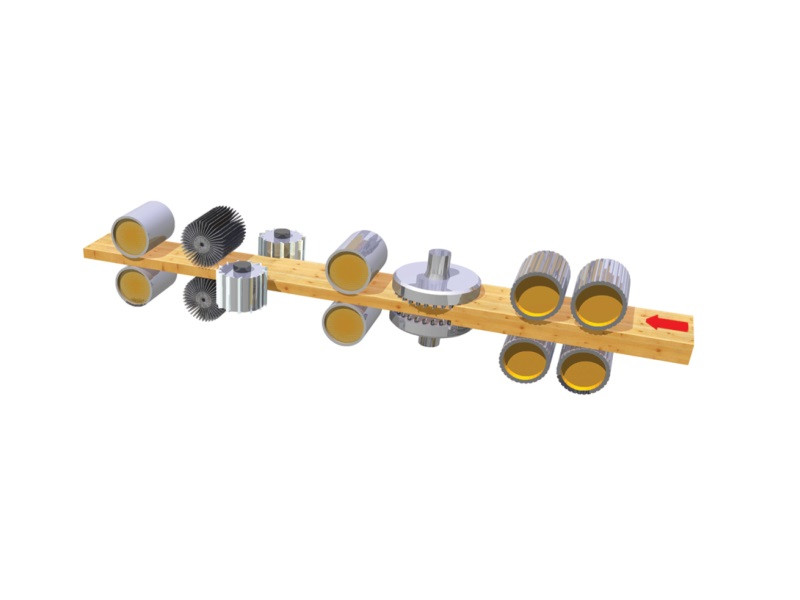

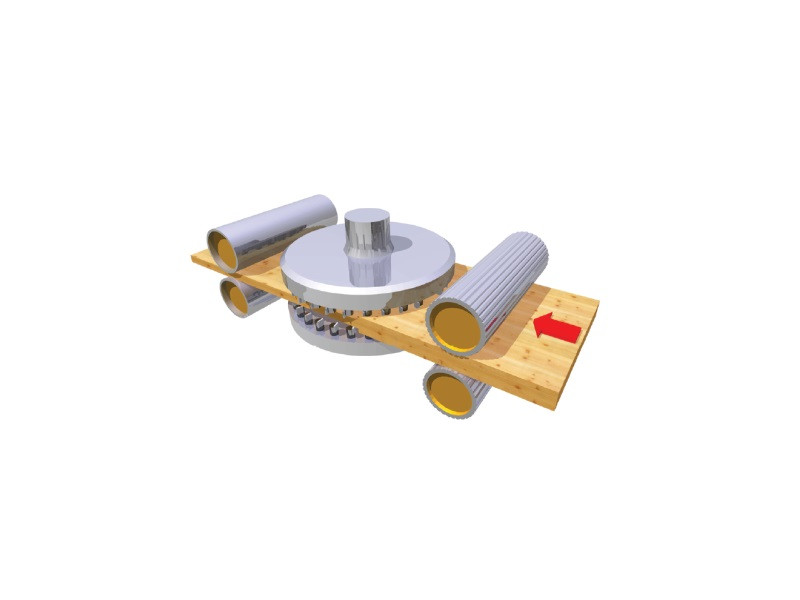

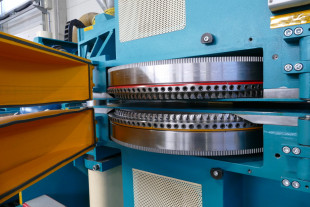

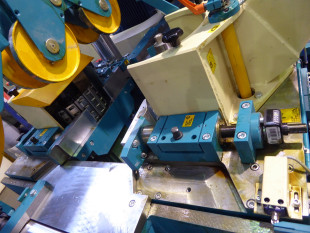

The ROTOLES 300 KS and ROTOLES 600 S milling machines use opposite or offset Rotoles rotors for machining of the top and bottom side of the boards and Rotoles rotors or hydro cutters on conventional spindles for machining of sides.

The machines are built with a fixed table and equipped with hard chromed plates and a roller feed for transport of workpieces. A very narrow and curved gap for cutters ensures very smooth, shock-free transport of workpieces whithout planer snipe.