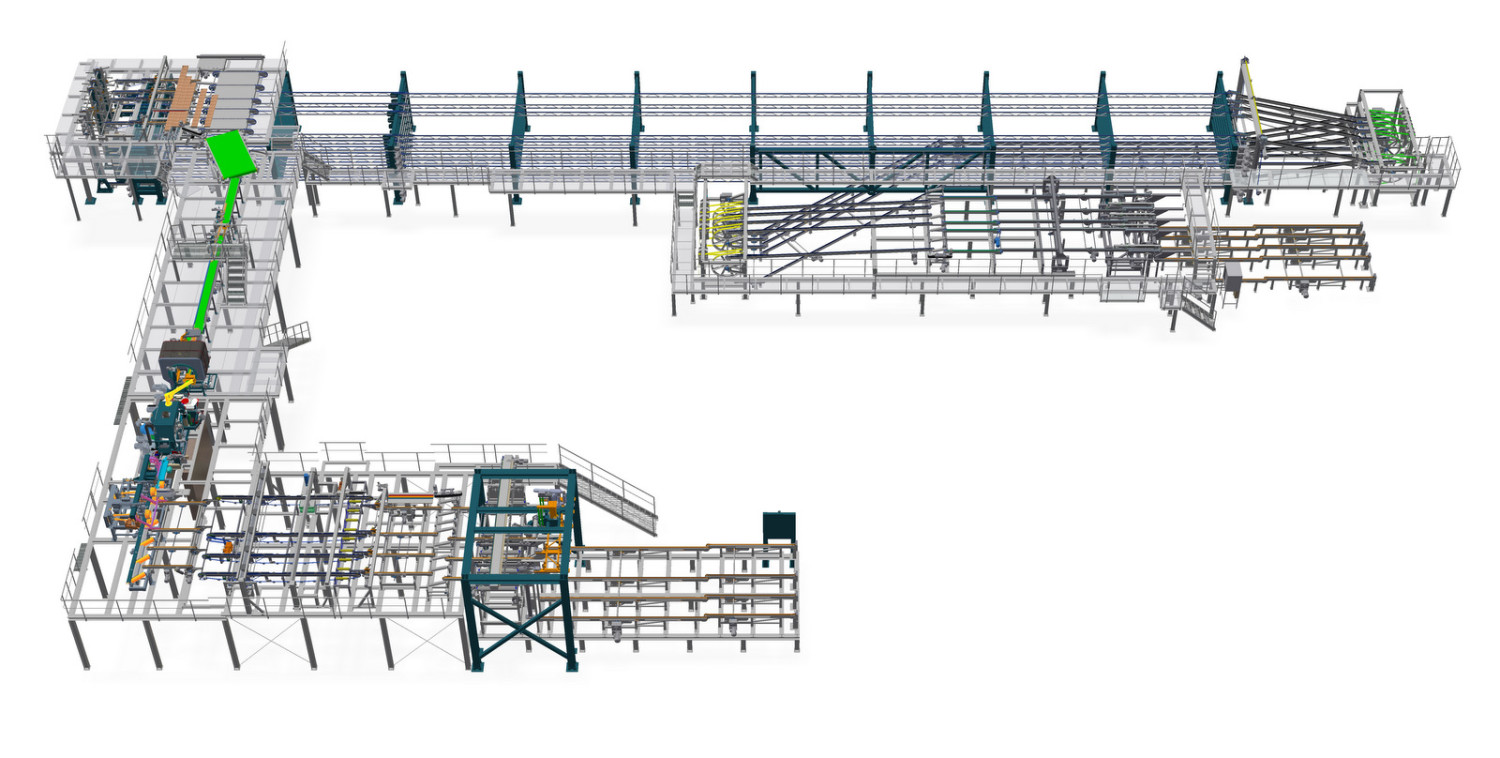

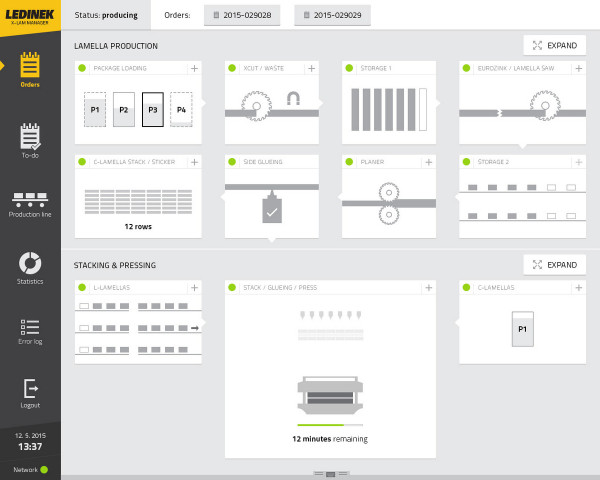

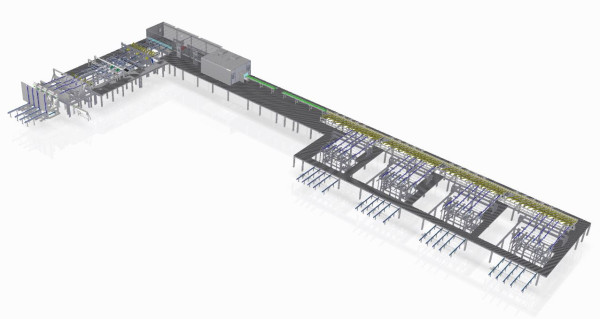

300 m/min grading and sorting line with 8 film tray storages

In the course of the investment of an Austrian customer in optimal raw lamella handling as well as their preparation after the purchase or for the further production LEDINEK built an automated high-performance sorting line for the pre-planing or calibration, assessment and sorting of lamellas, which are intended for the production of cross laminated timber.

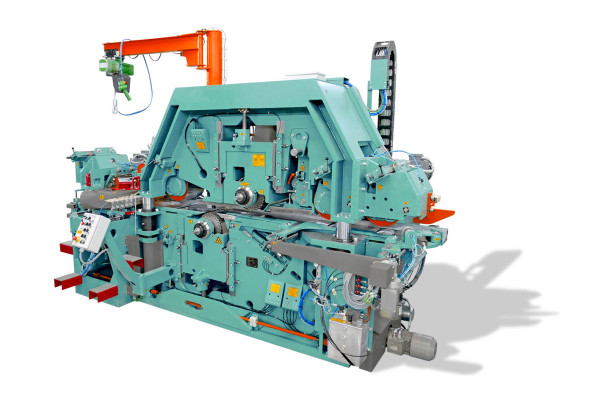

The requirement of the customer to LEDINEK was to ensure optimal pre-planing, sorting, incoming goods inspection or material tracking and data transfer for each sorted package to the in-house warehouse management program. The used planing machine STRATOPLAN with active float allows not only dimensional calibration but also the reduction / optimization of the purchasing and / or calculation measure by exclusive planing of the respective existing oversize - and that with thickness and width.

The Hobel sorting line was designed for an annual output of approx. 150 to 175,000 m³ in two-shift operation.

Case

- Package storage

- Vacuum de-stacking

- Detection of cup & annual rings

- Moisture Meter in cross direction and after the planer also longitudinaly

- Curvature measurement in transverse transport

- pre-planing with wood saving Stratoplan with active floating

- Strength grading by Scanner

- Automated marking (quality and defects)

- Sorting in Film tray storage

- Packaging with transfer of the package data to the warehouse management program

Key components of the solution

- Reception of packages, scan and manage the package data

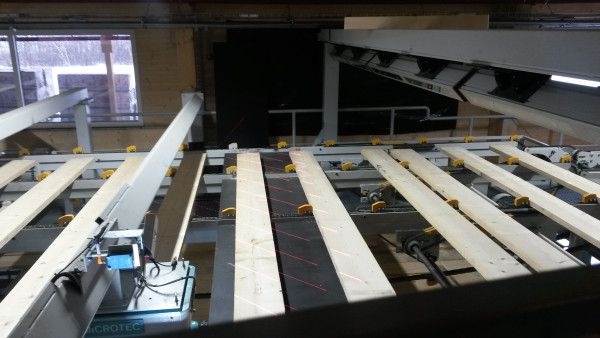

- Vacuum de-stacking with up to 10 layers per minute

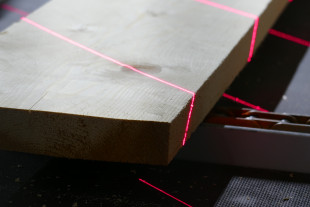

- Microtec Optiside year ring and cup detection with automatic board turner

- Moisture measurement M3Scan across and after the planer also along the board

- Curvescan curvature measurement in transverse transport

- Pre-planing or calibrating with STRATOPLAN with active floating at up to 300m / min.

- Mechanization designed for 60 machine cycles/minute

- GOLDENEYE 702 X-ray scanner from Microtec

- Ink line marking station for cutting and quality markings

- Sorting in 8 film trays with 50m length each to receive a complete package

- Space-saving feed into the floors and adapted arrangement of the entire system

- Packaging with transfer of the package data to the warehouse management program

- Operation of the system with 2 persons

- Complete system including Host computer from LEDINEK, (scanner from MiCROTEC)