Rotopress

Turn to commissioning goods

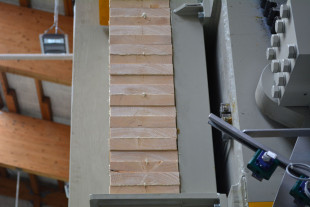

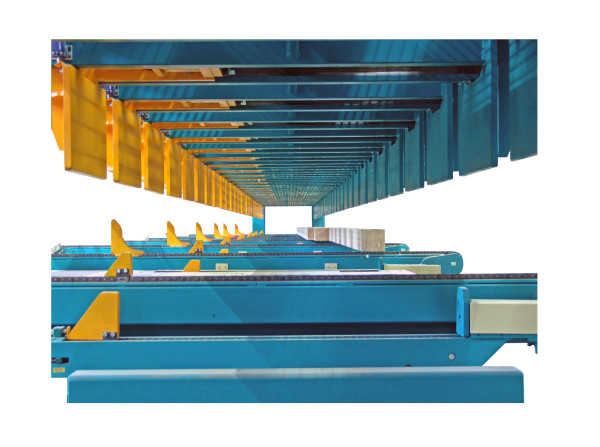

Rotopress is the fastest pressing solution for production of glulam. A rotating press with 4 press beds was designed especially for use of glue with extra short curing time and has challenged its progress over an entire decade. Fast stacking system and optimized process, plant and environmental control, enable shortest cycle times.

Glulam production with the Rotopress is highly adaptable. It can be used for production of smallest batches down to batch size 1, ensuring extreme adaptability for commissioning goods. Even the stepped batches can be stacked very fast, thus optimizing the utilization and capacity. When fully loaded, the press can produce large volumes of glulam and is therefore also a true high capacity machine.

Highlights:

-

Designed for batch size 1

- Capable of high capacity

- Straight glulam

- Stepped batches

- 4 pressing beds

- Up to 27 m of length

- Motorized clamping

- Short loading and curing time

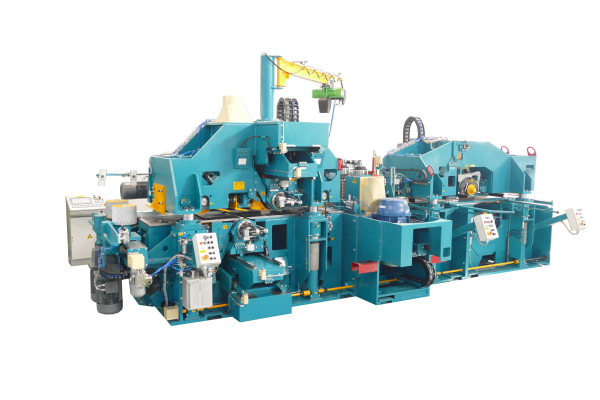

Advantages of motorized clamping

-

Individual motor for each clamping unit

- No hydraulics – no leaks that could damage the timber

- Exact adjustment of press force

- Efficient consumption of energy