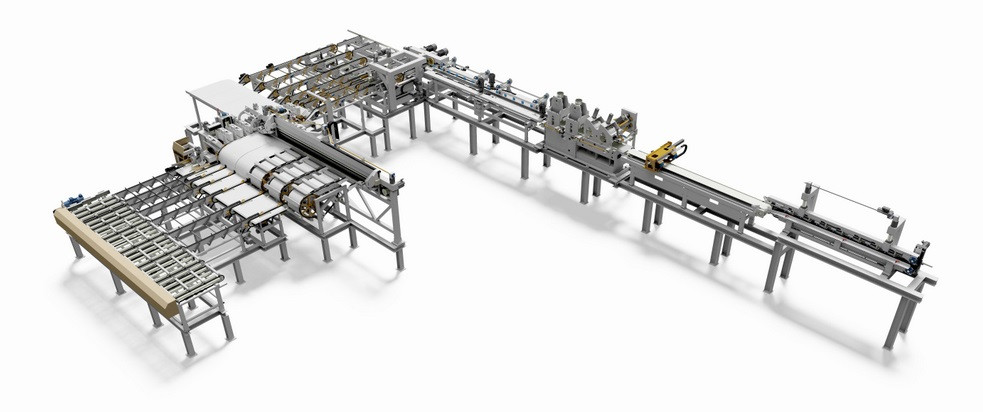

Kontizink 2500

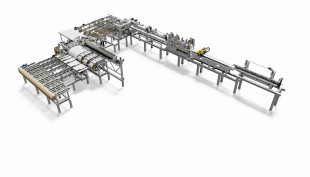

Innovative production with the most important benefits of the KONTIZINK line. Excellent finger joint quality and high productivity.

Effective production also requires an effective machine, tailored to the requirements of an expanding enterprise. This machine is exactly that: everything what is necessary.

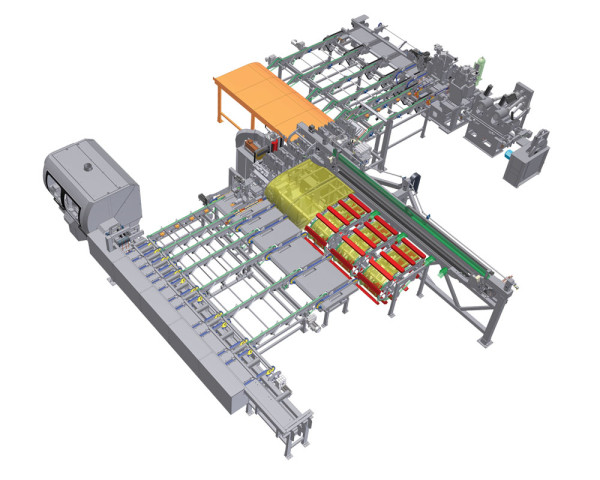

A high capacity single vertical finger milling system, assembly track and powerful but fast hydraulic press. All proven components providing highest output in the most efficient way.

Highlights:

- Maximum productivity

- Short and long lengths (up to 6m) can be processed after another

- Low milling speed

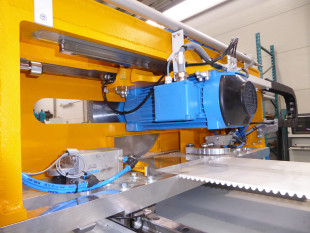

- Low-maintenance and reliable mechanical clamping of every single wood

- Each workpiece is individually aligned and machined

- Due to the individual clamping the joint is very accurate

- Large workpiece cross sections possible

- Very strong hydraulic cycle press

- All common types of adhesive can be used

- Separate computer-controlled glue application for melamine adhesive and hardener

- Positioned crosscut saw

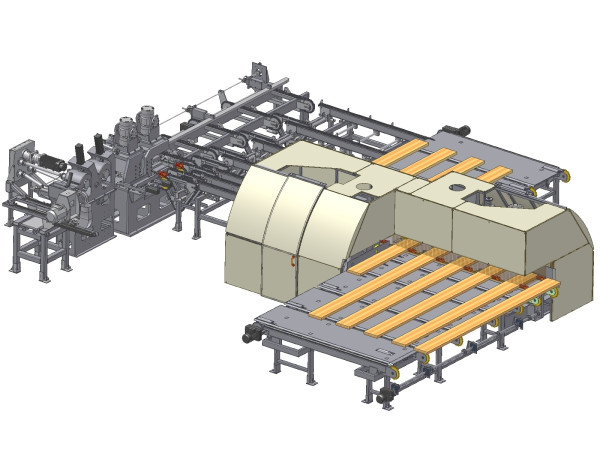

Benefits of the single piece vertical finger milling system:

- Excellent alignment of finger joints

- Every workpiece is independently aligned against reference surface

- No addition of thickness deformations in the package

- Uniform application of glue on every workpiece

- Insensitive to the variable lengths of the workpieces