Complete CLT Facility Installed at Mosser

Mosser Leimholz, a well-established company in Lower Austria's timber industry, has made a significant milestone in their corporate history by engaging in cross-laminated timber production. This strategic move not only underscores their commitment to innovation and quality, but also their confidence in choosing the right partners to achieve their ambitious goals. A key decision in this process was selecting Ledinek as the main equipment supplier for their new production line, a choice marked by deep strategic thinking and a clear understanding of the technological requirements for modern wood processing facilities.

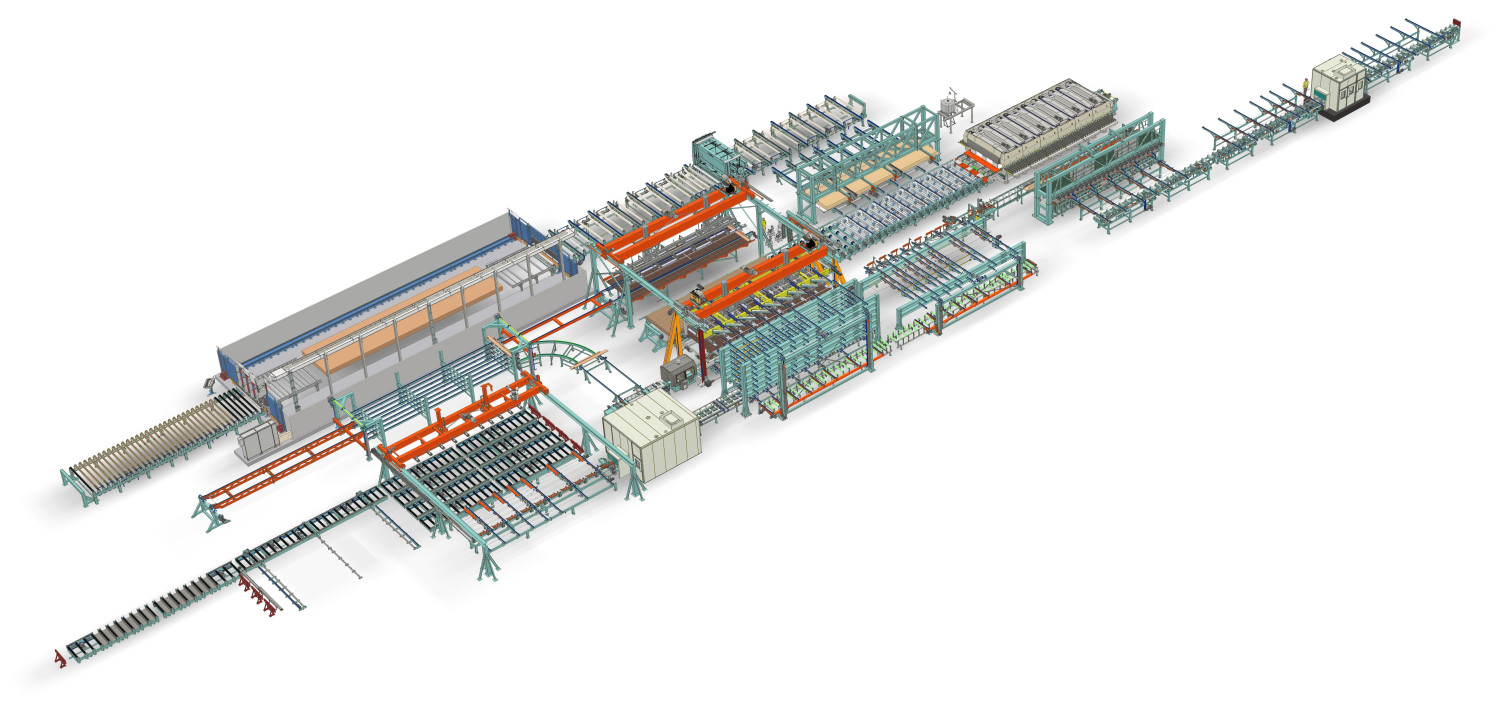

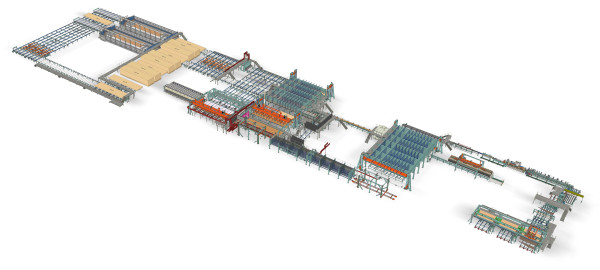

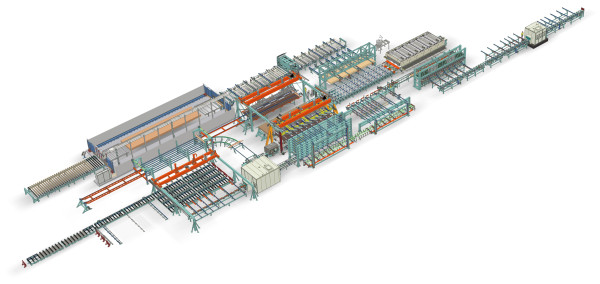

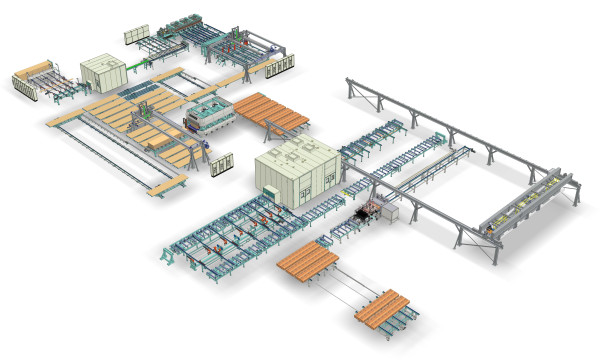

The choice fell on Ledinek, a globally recognized specialist in woodworking machinery known for its custom solutions and the exceptional quality of its equipment. This decision was based not only on Ledinek's technical expertise and the reliability of their machines, but also on the positive experience Mosser Leimholz had previously had with Ledinek in other areas. Ledinek's ability to offer a completely integrated production line, ranging from raw material handling to the finished product, played a crucial role. This complete solution promised an optimized production chain, minimized interface problems, and ensured high efficiency and quality of the end products.

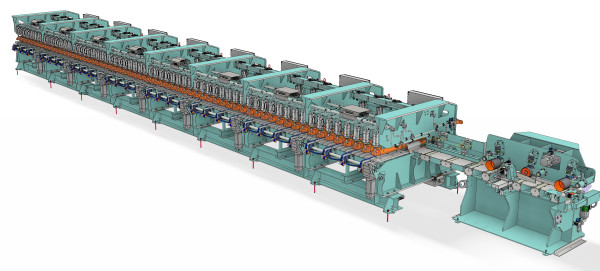

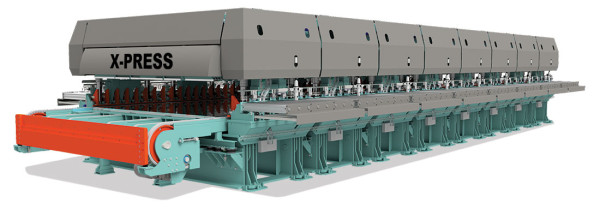

The entire production process was meticulously planned to meet the high standards of Mosser Leimholz. Starting with the precise handling of the lamellas by a vacuum lifter, through the state-of-the-art planing and finger-jointing facilities to the final pressing and surface finishing, each phase of the manufacturing process reflects the pursuit of perfection. Special attention was given to the selection of adhesives and pressing processes, with Mosser consciously opting for 1K-PUR adhesive and cold pressing techniques to meet the demands of modern cross-laminated timber.

Furthermore, the facility allows the production of panels in custom sizes, directly responding to market requirements. The flexibility in production, supported by Ledinek's advanced technology, enables Mosser Leimholz to efficiently serve a wide range of customer needs, from standard sizes to special custom orders.

The collaborative partnership between Mosser Leimholz and Ledinek, marked by mutual trust and the shared vision of a state-of-the-art CLT production facility, has enabled the realization of a project of exceptional technological and ecological value. The facility, designed for an annual output of 50,000 m³, sets new industry standards and confirms the role of Mosser Leimholz as a pioneer in the processing and finishing of wood products.

Company: Mosser Leimholz GmbH

Website: www: www.mosser.at

Location: A-3263 Randegg

Project Manager: Herbert Spahn

Operations Manager: Erich Faffelberger MSc

Employees: 30

Timber species: Spruce

Production Capacity: over 50.000 m³ / Year