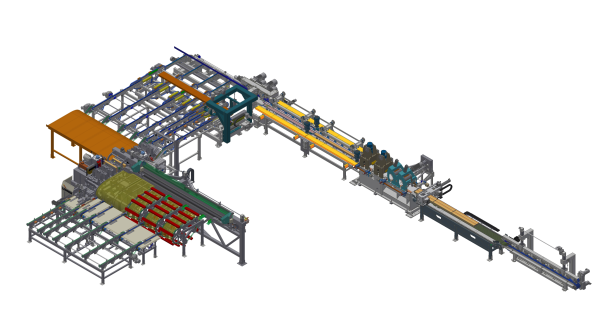

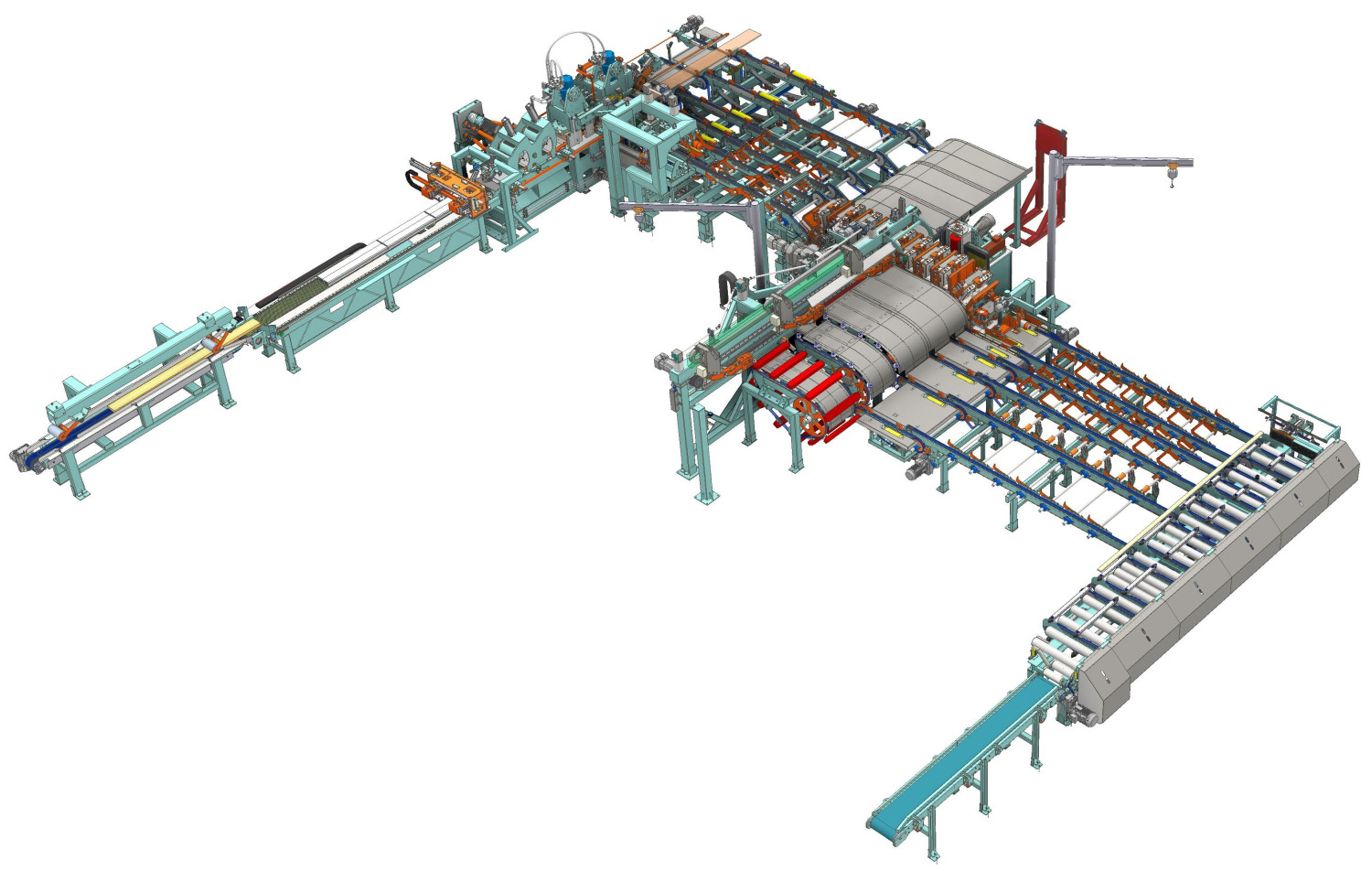

Kontizink 2000

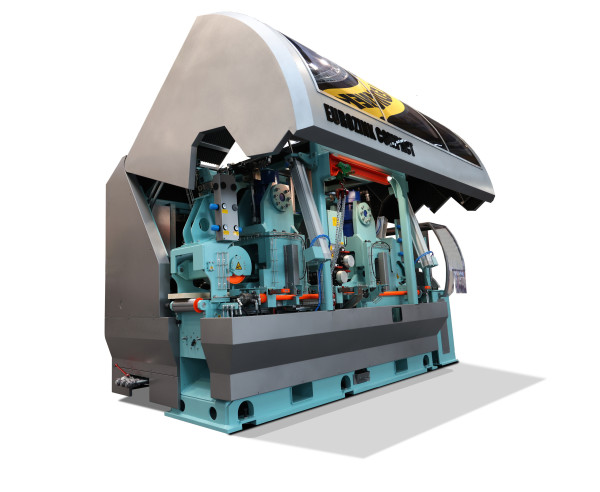

All the benefits of our finger jointing lines in one machine, superb finger joint quality and high pressing power of the hydraulic press. This machine is also suitable for solid construction timber.

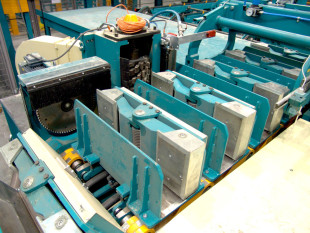

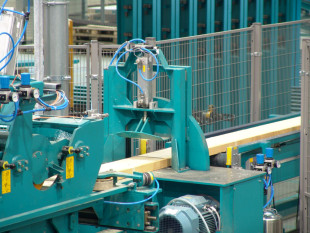

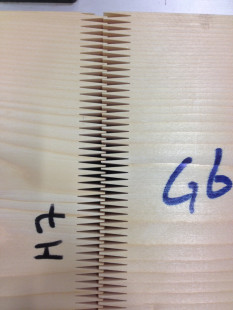

Single piece vertical finger joint milling system with chippers creates a very exact finger form at a low feeding speed, therefore producing a high quality finger joint with excellent physical and visual characteristics. Machine can be equipped with polyurethane or melamine glue applicators and suited for every type of production. A strong hydraulic press is designed for biggest cross sections and can handle boards for laminations as well as solid construction timber. This adaptable machine is perfect for any type of versatile production.

Highlights:

- Maximum productivity

- Short and long lengths (up to 6m) can be processed after another

- Low milling speed

- Low-maintenance and reliable mechanical clamping of every single wood

- Each workpiece is individually aligned and machined

- Due to the individual clamping the joint is very accurate

- Large workpiece cross sections possible

- Very strong hydraulic cycle press

- All common types of adhesive can be used

- Separate computer-controlled glue application for melamine adhesive and hardener

Benefits of separate application of melamine glue:

-

Separate application of glue and hardener to opposite ends of the board

- Components mix during pressing

- Individual application systems

- Easy setup of volume

- No contact before pressing

- Longer standstill periods without cleaning

- No mixing unit required