Unipress

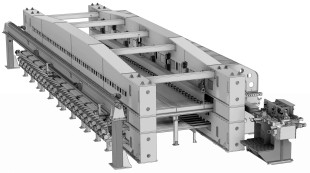

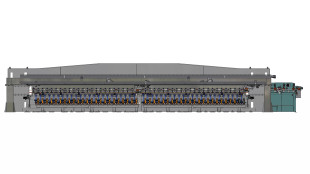

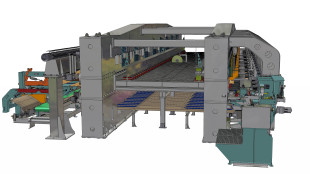

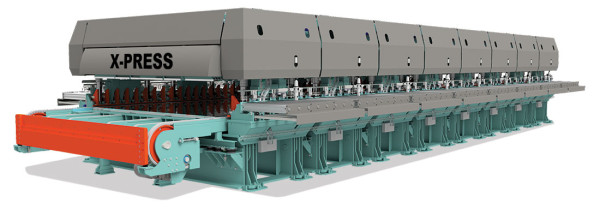

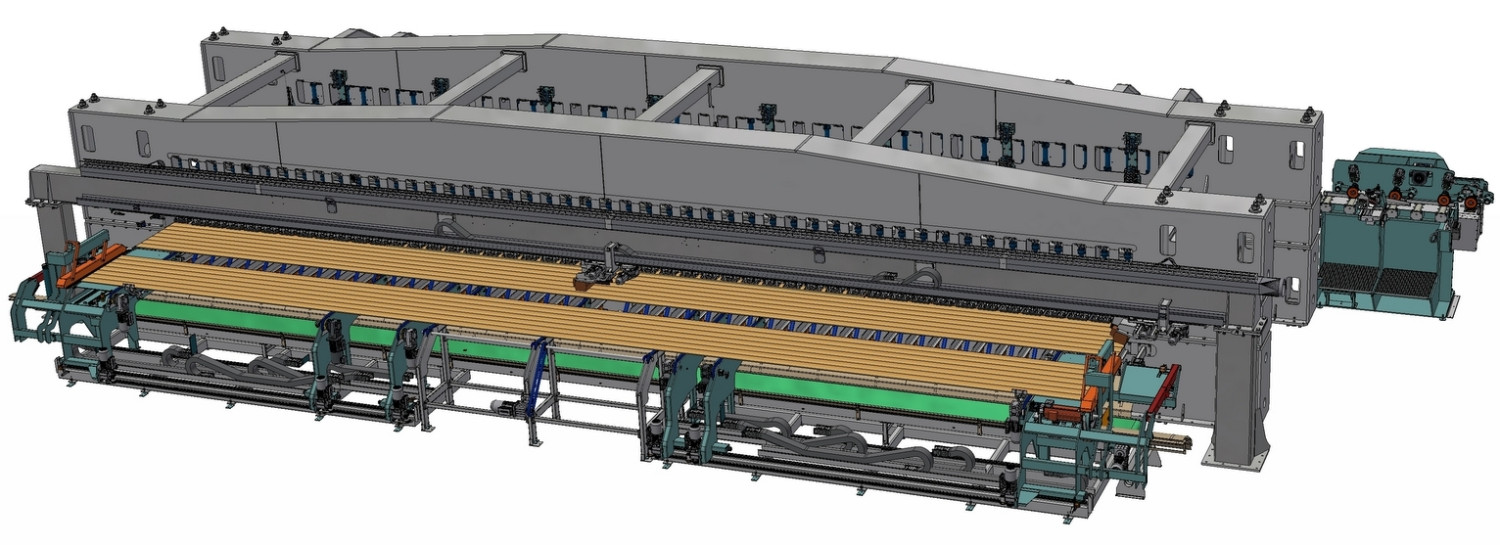

UNIPRESS is a continuously working cold edge gluing plant with through feed for production of solid wood edge glued panels, is a true king of productivity. Imagine an endless panel streaming out of the press. This is it, slow but continuous, summing up to a high production volume.

This type of continuous pressing can be applied on a wide range of products; therefore, we make a range of tailor made pressing solutions for various applications up to 16 m panels for cross laminated timber. Always fully automated and of highest quality, efficiency and productivity. You can choose from a wide range of our automaton solutions, or have them made especially according to your requirements. We always provide complete solutions from one supplier, optimizing the entire process to perfectly match the requirements of your enterprise.

Special features:

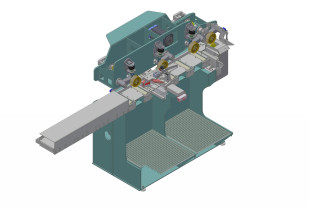

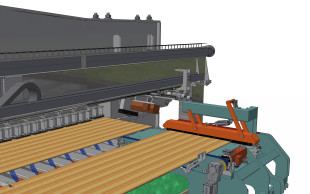

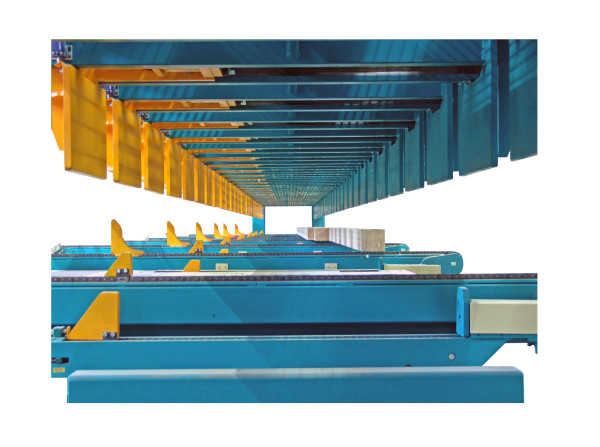

- Precise longitudinal servo positioning of the laminations before feeding into the press

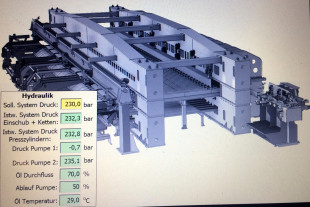

- Special lamination feed system, separated synchronically moving hydraulic pushers with 0,1 mm movement accuracy

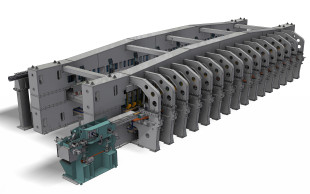

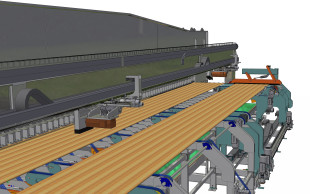

- Continuous production of endless solid wood panels

- Single driven back-holding chains with lugs for fast emptying and feeding of the press at dimension change

- Double flying cross cutting saws - accurate and fast cutting of endless panel to the user defined panel width

Highlights:

- High capacity production of edge glued panels

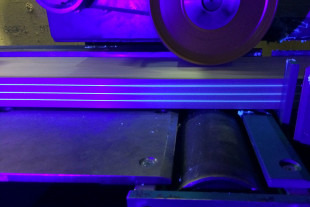

- Cold press – no heat input - no high radio frequency

- Continuous output at length change

- Maximum quality and precision of machine and end product

- Automatic loading and unloading

- Automatic cutting of panel length during through- feed. The saws are automatically adjustable to requested panel length

- Automatic width cutting of the panel. The required width is automatically adjustable