Ante invests in CLT manufacturing facility

Another company in the Central European timber industry sets the course for the future. From now on, the ante Group produces CLT elements for walls and ceilings under the HBS Berga brand. The traditional company is taking the step to become a full-range supplier. Ante has been supplying its customers with products such as sawn timber, planed goods, KVH, glulam and CNC joinery for home and garden needs as well as ecological bio-electricity and pellets for 90 years.

Cross-laminated timber for modern wall and ceiling constructions form the perfect addition to the range of services. The decision to complete the entire product range with cross-laminated production for solid timber construction systems has matured in recent years.

Berga is only five kilometres away from the ante plant in Rottleberode, Saxony-Anhalt, which went into operation in 2007. Existing production halls available for the CLT production, CNC joinery, commissioning and storage with direct motorway a rail connection form the perfect infrastructure to locate a business.

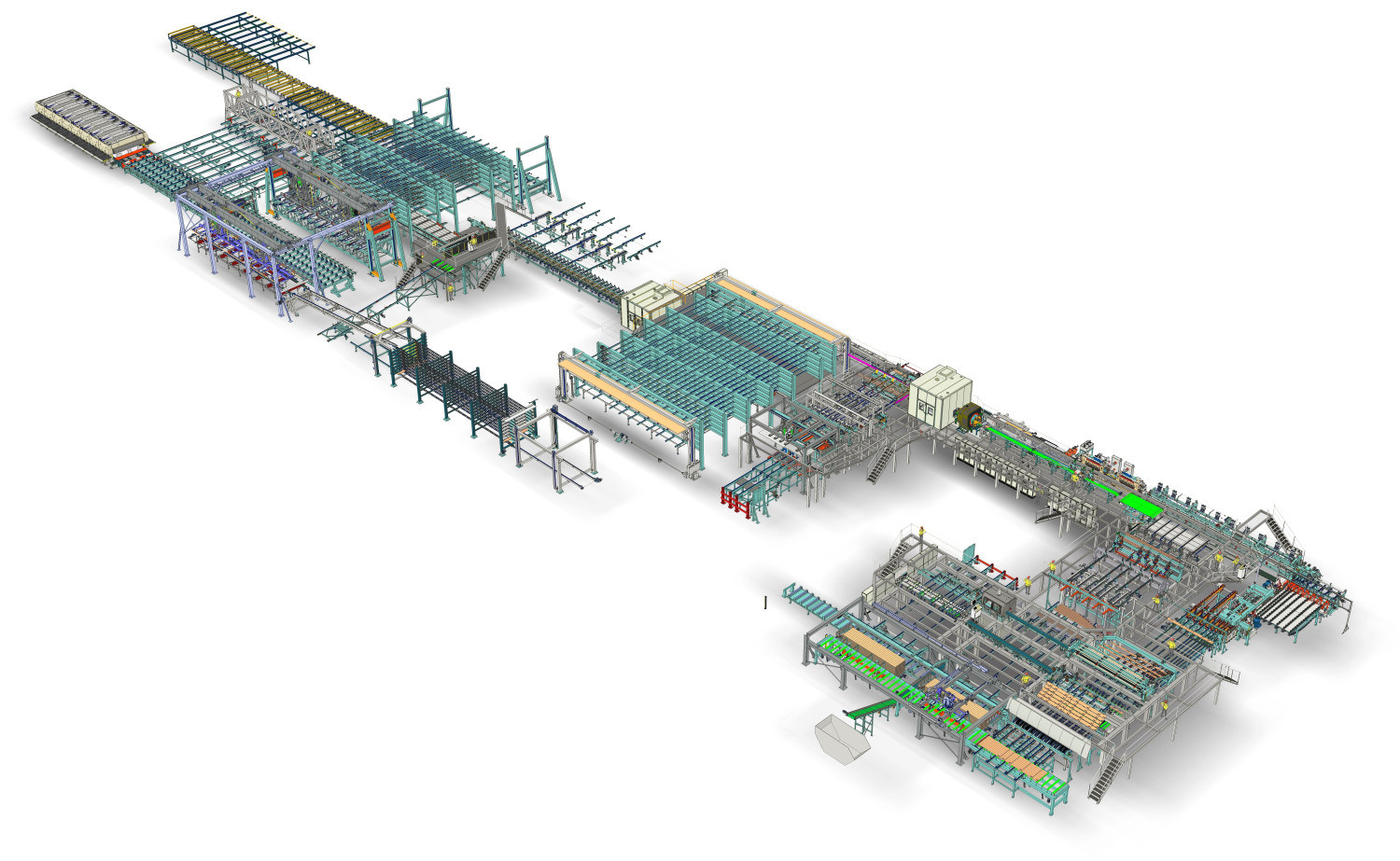

When building the CLT line, the family-managed company based in Bromskirchen-Somplar in northern Hesse relies on the latest knowledge and technical standards. In mid-April the decision was made in favour of Ledinek as the main supplier. The decisive factor was our great experience with CLT technology. "We are convinced of the innovative approach and the coherent system concept", says ante managing director Jürgen Ante. This avoids unnecessary or problematic interfaces.

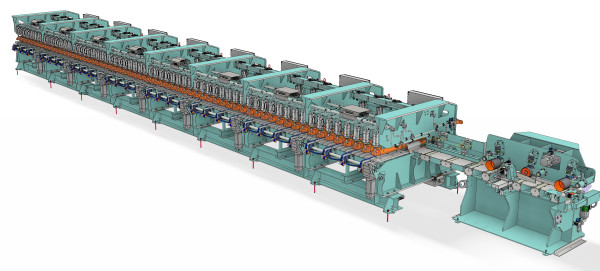

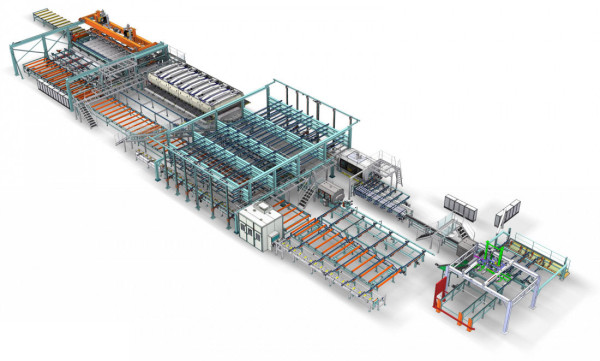

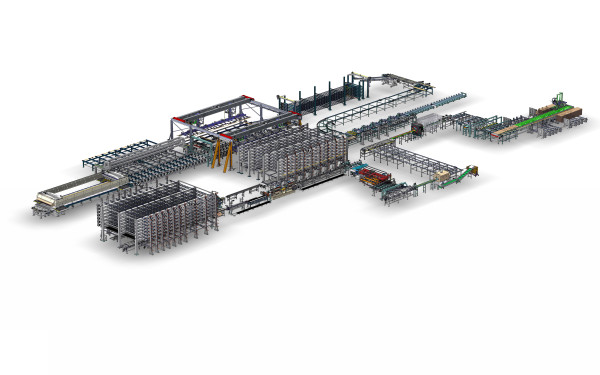

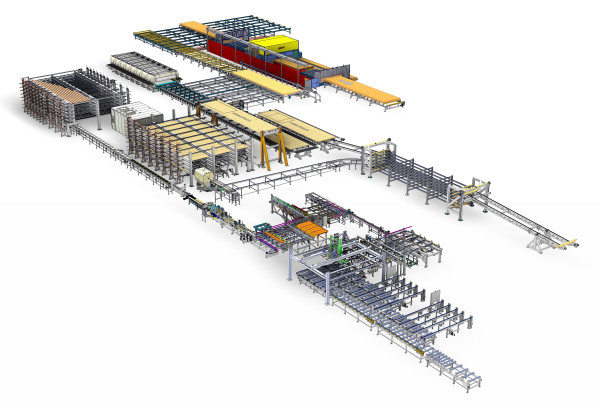

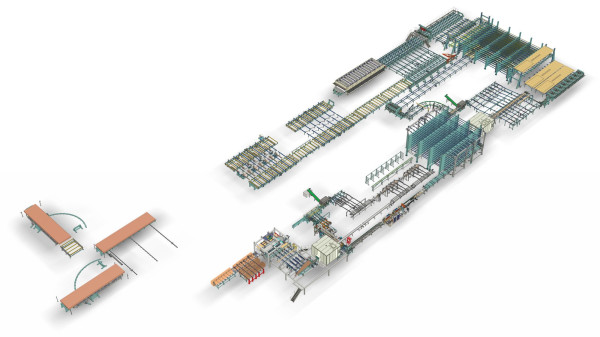

Ledinek will supply everything from the raw wood infeed to transporting the raw CLT elements to the sending machine or to the CNC machining centres - including the PC process control system "X-Lam Manager"!

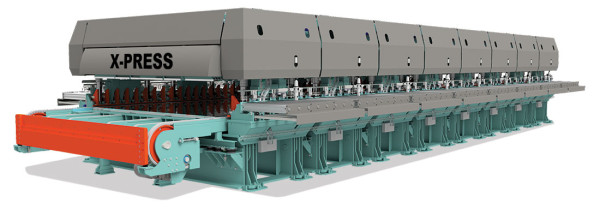

When completed, HBS Berga CLT will be able to produce up to a capacity of more than 100,000 m³/A. Elements of up to 16m x 3.5m x 360mm are to be manufactured. The individual layers will be prepared with the Z-Press into single-layer glued wood panels, which promises airtightness and a higher capacity of pressing in X-Press.

Location: Berga Sachsen-Anhalt / Germany

CEO: DI Jügen Ante

Project leader: DI Hubert Teufel

Employees: 50

Timber species: Spruce

Production capacity: over 100.000 m³ / Year

Turnkey CLT production

- Feedstock package intake, vacuum de-stacking, loading into the measuring chain

- Moisture control, detection of twist, spring, bow and cup with turning device

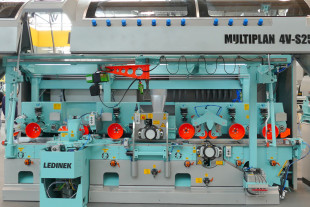

- SUPERPLAN 4V-S400 4-sided pre-planer

- GOLDENEYE 702 SCANNER with marking station

- Stacking machine for sorted and marked boards

- Roller conveyors and chain cross conveyors for buffering the packages

- Unstacking by layers for 2 qualities with vacuum de-stacker

- Roller conveyor for layers, chain transporters with singling and loading into lug chain

- Detection of the boards marked with fluorescent ink in the transverse passage

- Bypass loop with X-CUT S400 defect chop saw with infeed

- KONTIZINK L-S120 with separated melamine finger joint glue application

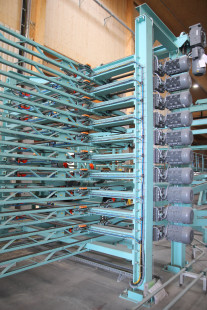

- Curing deck with 5 levels per level divided into two

- Superplan 4V S400 lamella planer with output for KVH stacking machine

- Hot-melt edge gluing Z-PRESS for fast assembly bonding of solid wood laminations

- CLCS 1600 Cross-cut saw for cross lamination panels

- Multi tray storage (8 trays) for edge-glued cross lamination layers

- Multi tray storage (5 trays) for longitudinal laminations – bonded to single layer panels

- Vacuum layer assembly unit with PUR (1K Polyurethane adhesive) surface gluing

- X-PRESS 16 - cross laminated timber press with up to 0,8 N/mm² pressure

- Cross CLT panel push off unit with outfeed roll conveyors

Facts

- Panel size up to 16 m x 3,5 m x 0,36 m

- Production capacity up to 100.000 m³/year

- Shift production up to 150 m³

- Integrated edge-gluing system with hot melt adhesive

- Fast PUR (1K Polyurethane adhesive) for surface gluing with cold setting

- Very short pressing cycle

- High flexibility of the CLT production process