Finger jointing line for Stora Enso new CLT production in Zdirec

Mr. Herbert Jöbstl, Head of Operations, Wood Product SE:

“As in many previous projects, Ledinek has once again demonstrated its competence and reliability in the supply of plant-areas for our CLT plant in Zdirec.”

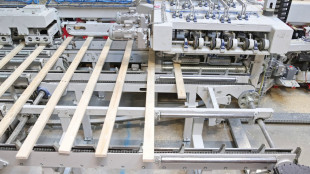

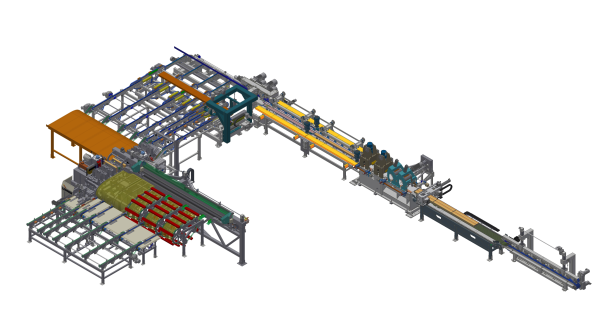

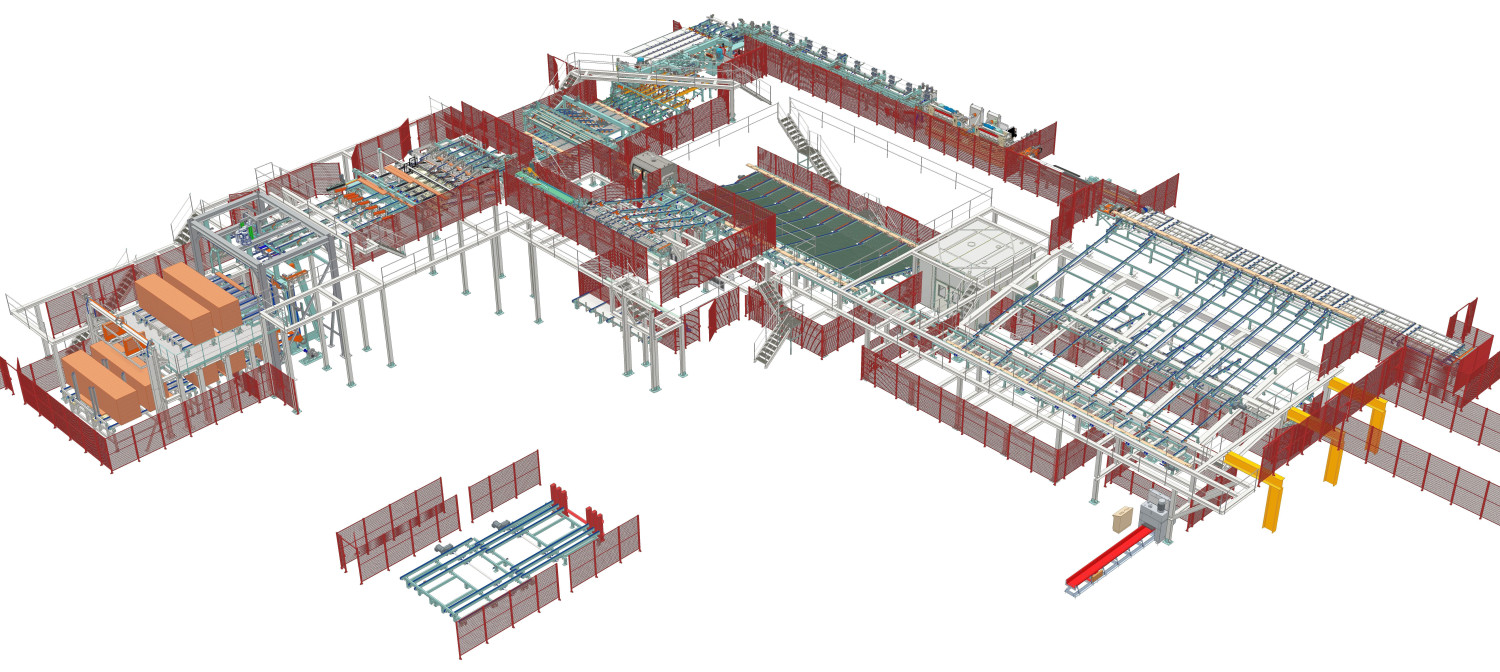

For our customer Stora Enso, who have already built their fourth CLT line, we have delivered for about a third of the whole equipment for their new project in Ždirec, Czech Republic. The Ledinek plant consists of the infeed equipment, which represents the first part of mechanization and delivers wood to our machines for cutting out the defects (X-CUT S400) and for finger jointing (Kontizink H 5000).

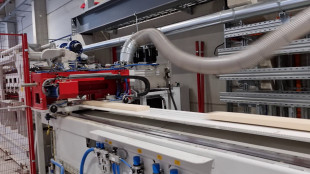

The second part of the mechanization belongs to our planer Superplan 4V-S250 and delivers wood to the machine and after the planer to the press for single-layer panel production. Both the mechanical and electrical installation were completed according to schedule, and we thus also started test production on time, which was an important milestone for both the Stora Enso and Ledinek teams. This will now be followed by the optimization of production and the training of the operators at the plant.

As well, we delivered to the customer two feeding machines Powerfeed 70-S350 and the Superplan 6VR-S350 planing machine for their sorting line. The equipment is in the commissioning and testing phase.

Despite all the challenges we had to overcome over the past months due to the epidemic and extended delivery time for material, the project is progressing well, and we are looking forward to finishing it successfully. The biggest credit here goes to the Stora Enso and Ledinek teams and their good cooperation on the project.

We wish the Stora Enso team all the best and a lot of success with their new investment.

Company data:

Company: Stora Enso Wood Products Ždirec s.r.o.

Location: Ždirec nad Doubravou / Czech Republic

Head of Operations Wood Product SE: Herbert Jöbstl

CEO Stora Enso CZ units: Frantisek Vicha

Project Manager: Markus Weiss-Moser

Employees: approx. 110 (4 shift operation)

Species: Spruce

Production capacity: 120,000 m³ / y (4 shift operation)

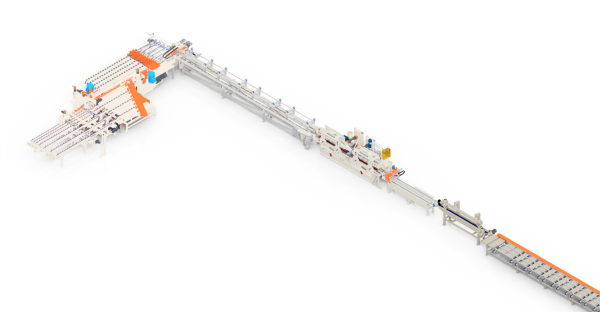

High performance finger jointing line

10 Loading and unloading of packages by crane

20 Cross Conveyor for incoming packages, with takeover station from crane

30 Scantling pusher placed between packages for stacking

40 Vacuum-destacking unit

50 Chain and roll conveyor for aligning with life belt stop

60 Cross conveyor with single piece feeder

70 Lug chain conveyor with measuring sensors

80 Double Flipper to X-Cut bypass Line

90 Infeed to the markings reading station LUT

100 Infeed X-CUT 400

110 X-CUT S400

120 Transporters after X-Cut with infeed to finger jointer

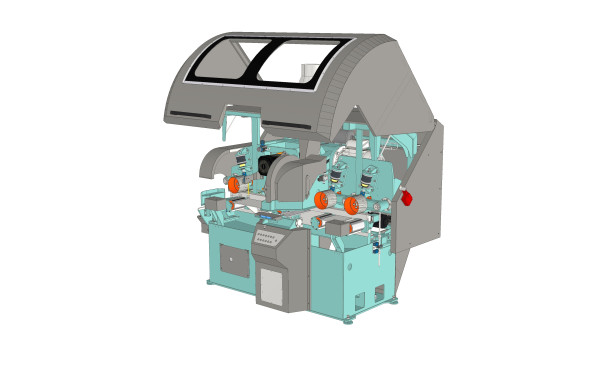

130 KONTIZINK LH-S160

140 KONTIZINK flying saw unit - patented

150 Rollcase conveyor with side sweep lug chain

160 Aligning roller conveyors

170 Buffer cross curing conveyor for single lamella

180 Optifeed 70-S350

190 Superplan 4V-S350

200 Team Ledinek

Facts

- Width 70 - 250 mm

- Thickness 19 - 60 mm

- Cycles 100 1/min

- Typical capacity 5.000 m/h

- Feeding speed 160 m/min

- Diameter of finger cutters 350 mm

- 200 m³ Shift production

- Production capacity up to 100.000 m³/year

- PUR glue used for higher capacity

- Totall installed power: app. 1.790 kW

- Dust extraction requirement app. 82.600 m³/h