Turnkey production of cross laminated panels

We are pleased to share the news of a successful cooperation between two outstanding Slovenian companies.

LEDINEK, a leading manufacturer of advanced woodworking machinery and technologies, has recently successfully delivered a complete production line for cross-laminated panels (CLT) to Stilles d.o.o., based in Sevnica.

This cooperation represents an important milestone in the Slovenian wood processing industry, as it is the first such production line in Slovenia.

Stilles, known for its quality and innovative furniture production, has entered a new era of production with this new acquisition. With the help of the high-tech Ledinek line, Stilles will be able to produce cross-laminated panels of the highest quality, which are a key building material for sustainable and environmentally friendly construction.

The new production line incorporates state-of-the-art technologies that enable the timber to be processed with precision and used to maximum effect. This means not only improved production efficiency, but also reduced waste and a higher level of environmental awareness. With Ledinek's equipment, Stilles will be able to produce robust and aesthetically sophisticated cross-laminated panels that meet the highest standards of modern construction.

Company: Stilles d.o.o.

Location: Sevnica / Slovenia

Timber species: Spruce

Capacity: 7,500 m³ / per Year

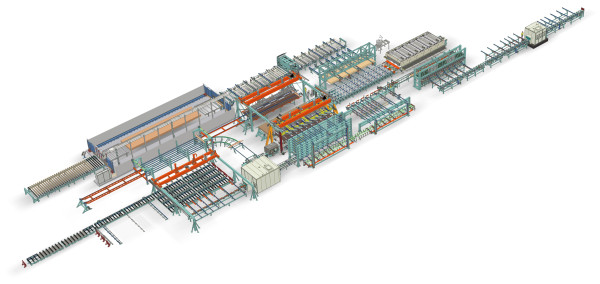

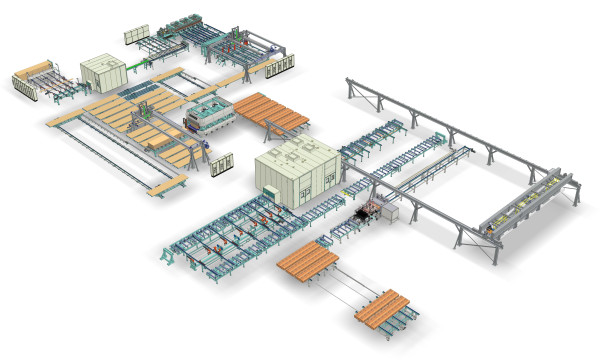

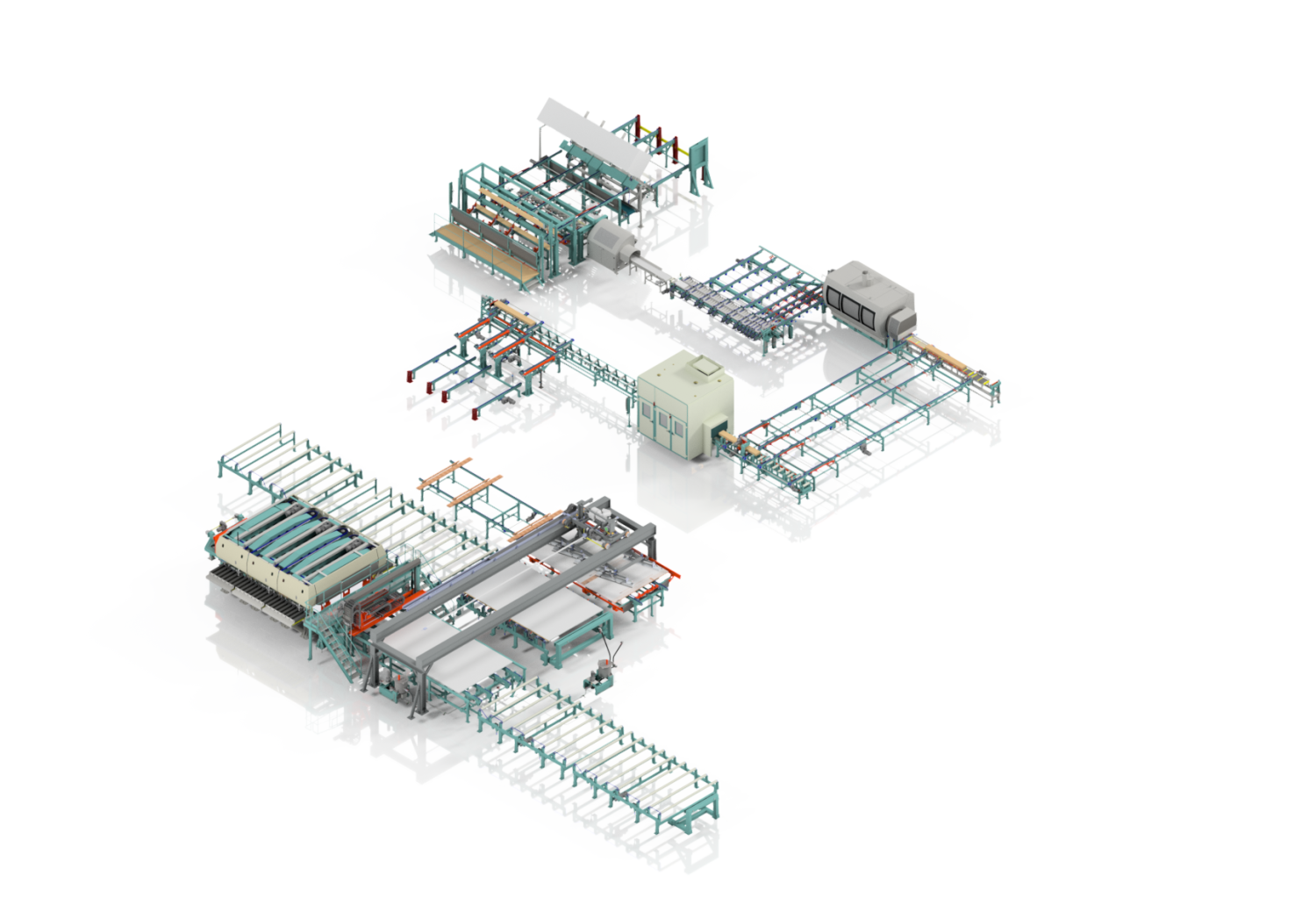

AREA B – Cross-Laminated Timber Production

11. Manual placement of longitudinal and transverse lamellas

12. Roller conveyor for intermediate storage of longitudinal lamellas (3 layers)

13. Alignment station for the longitudinal layer

14. Cross chain conveyor for intermediate storage of transverse lamellas (2 layers)

15. Alignment station for the transverse layers

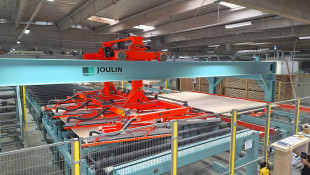

16. Vacuum unit for assembling panels for longitudinal and transverse layers

17. LEDINEK PUR (single-component polyurethane) adhesive application system

18. Robust, fast-moving aluminum table with PE coating for CLT panel assembly

19. X-PRESS 6 – Press for cross-laminated timber with pressing pressure up to 0.8 N/mm²

20. Unit for longitudinal transport of cross-laminated timber panels with outfeed conveyor

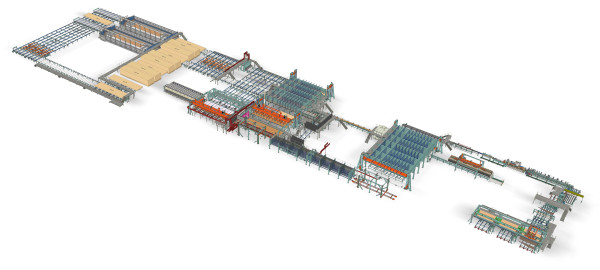

AREA A – Finger Jointing Line

- Tilt table for wood unloading

- Moisture measurement

- Manual marking station for defect identification in wood

- Device for removing boards from the line

- Cross-cut saw for defect trimming

- Feeding system for the finger jointing line

- Eurozink COMPACT 800 – Finger jointing machine with a capacity of up to 6 pieces/min

- Curing storage – 1 level

- EUROPLAN 4V+4F-S40 planer for lamellas

- Stacking device for package formation

FACTS

- Cross-laminated timber panels: up to 6 m x 3.5 m x 0.36 m

- Production capacity: up to 7,500 m³/year

- Production capacity per shift: up to 30 m³/shift

- PUR adhesive for high production performance

- High flexibility of the production process