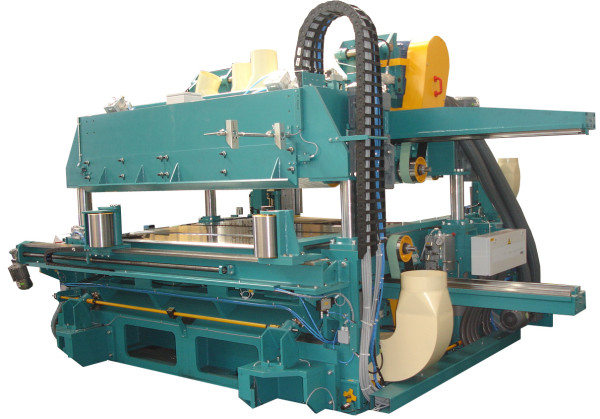

Polypress

Triumph of automation and form

A fully automated press for production of curved laminated beams. POLYPRESS is designed for batch size 1 operation – from the drawing to the press, without any necessity for manual labour. For the first time, a single curved beam can be manufactured in an efficient and quick way, presenting an excellent possibility for affordable realization of most complex wooden structures.

Automatic production of single pieces of curved laminated beams is enabled by a totally automated setting and manipulation on the press. Forming and pressing shoes are positioned with motorized drive, pressing is performed by short stroke hydraulic cylinders. Entire press can be supervised by one operator. The highest level of automation supports the use of glue with short curing time, enabling a short turnaround and high productivity of the press.

Highlights:

-

Batch size 1 for curved beams

- Automatic stacking and loading

- Motorized setup of geometry

- Automated side pressure

- Hydraulic pressing force

- Low consumption of energy

- Automatic pressure control and readjustment

- Automatic unloading

- Excellent repeatability

- Expandable modular design

Advantages of batch size 1:

-

All different workpieces

- Fast curing glue – high capacity

- Efficient production of most complex structures

- Highest production flexibility