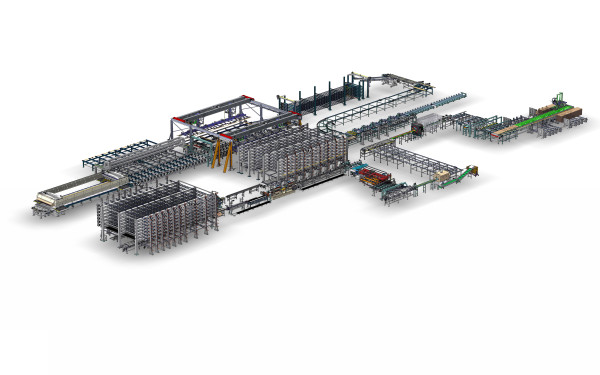

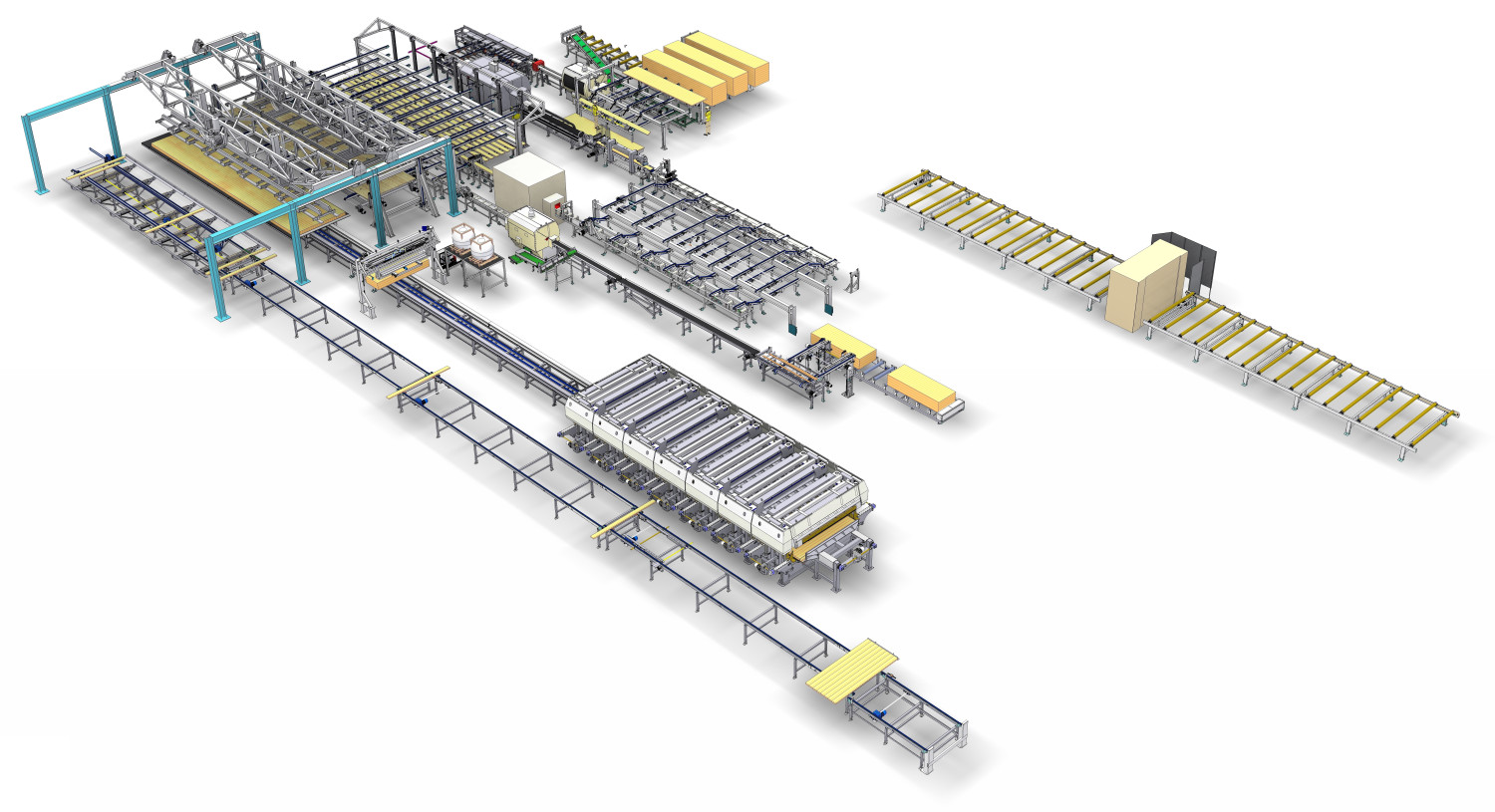

CLT production line NextGen

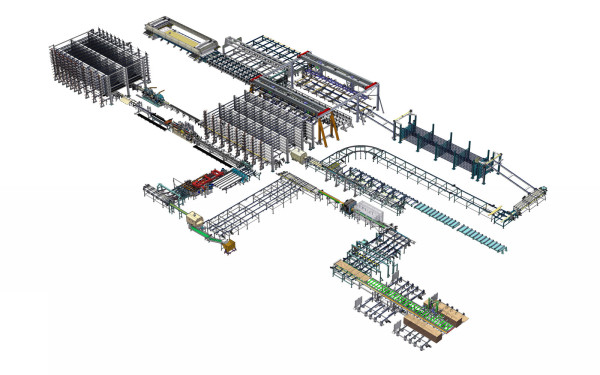

We adapt the production layout to your requests and integrate special equipment outside of our production portfolio. Moisture meters, strength graders, scanners, cross cut saw for defects, finger jointing machines, handling equipment, high performance planers, glue applicators, CNC joinery bridges or panel sanding machines are selected from the finest suppliers and fully integrated in the CLT line. All the interfaces are taken care of.

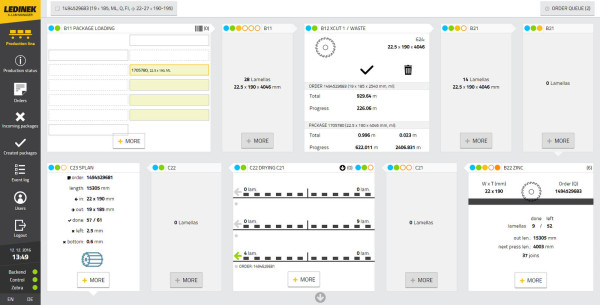

Different adhesive types, finger joints orientations, buffering systems, edge glue presses or other unique features of your CLT production line can be selected. On top we can integrate all machines under our specially developed X-Lam manager PC based control system with visualisation capabilities, production flow steering, statistics and production analysis capabilities. Let us know your requested CLT production figures and we will prepare for you a custom made budget offer with layout adapted to your building. Turn key solutions for complete CLT production lines from one hand.

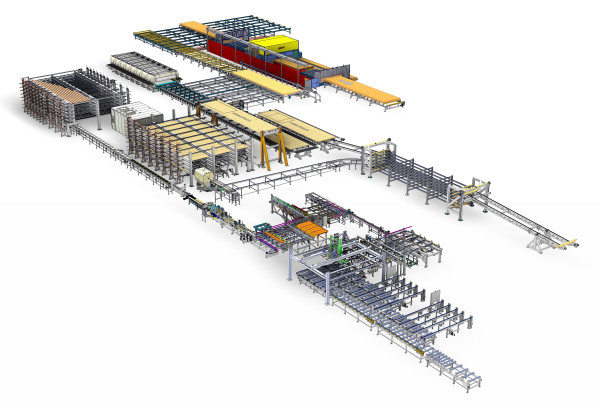

Showcase in Riga/Latvia

Complete CLT production factory

- Infeed system with vacuum de-stacker

- Moisture meter with grading and defect marking station

- Defect cutting saw X-Cut

- Metal detector

- Compact finger jointing machine with flying saw Eurozink Compact 8 joints/min

- Curing decks and buffer zone

- 4 side planer for lamellas Europlan 4V 120 m/min

- Tray buffer for up to 6 long layers

- Length cutting of cross lamellas X-Cut

- Stacking for cross layers

- Buffer for 4 complete cross layers

- Automated Vacuum assembly station

- Glue application unit for 1 component polyurethane adhesive

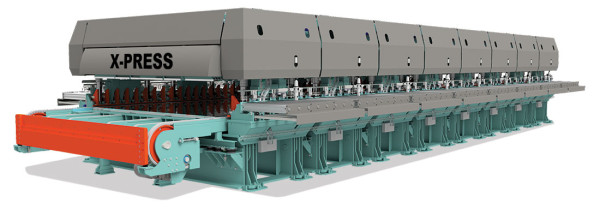

- CLT press X-Press 14m

- CNC joinery centre

- Wide surface sanding machine

Facts

- Up to 14 m x 3.2 m x 0.4 m panel size

- Up to 25.000 m³/year

- 50 m³ Shift production

- High flexibility of production

- X-Lam manager integration

- Precision cut elements by cnc machine PBA from Hundegger

- Perfect finish by sanding machine from IMEAS

- Dust extraction 80.000 m³/h

- Total installed power 1.100 kW