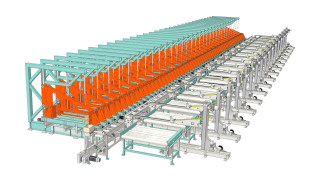

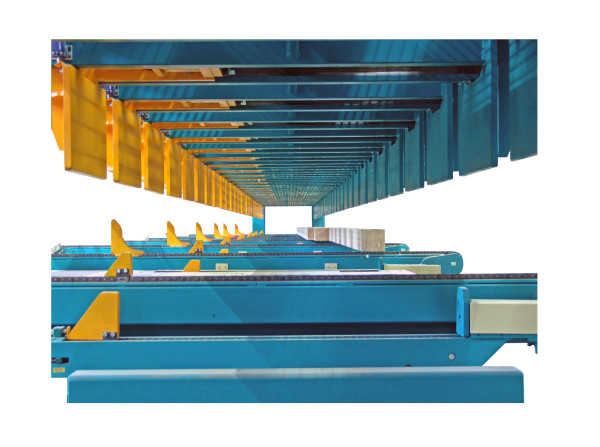

Flexipress Camber

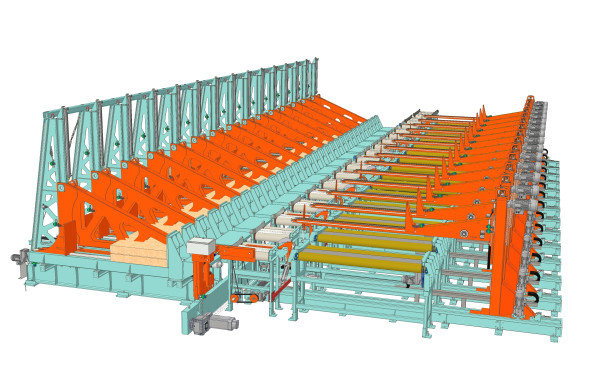

A high-performance automatic press for the flexible production of straight, tappered, cambered or curved glulam beams and also columns.

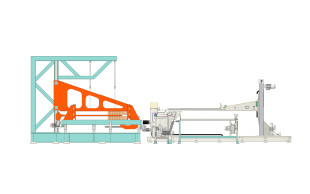

It allows quick adjustment to different GLT shapes and supports beam sizes up to 80 inches in height and 24 inches in width, ideal for both custom and commodity production. The system can also produce cambered or curved beams with up to 3 feet of camber height, making it a versatile solution for architectural or structural applications. The press uses fast cold-setting PUR adhesives, ensuring strong, durable bonds without the need for heat.

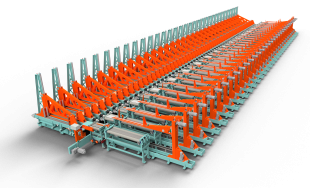

With motorized setup and hydraulic pressing, the FLEXIPRESS CAMBER easily adapts to changing production needs—whether for individual elements or high-volume output. Both clamps are motorized, enabling automated setup of the camber shape for fast and repeatable production. The system is fully automated, with driven manipulators for loading and unloading. A built-in side pressure system ensures fast closing times, ideal for fast-curing PUR or MUF adhesives.

Multiple stepped layers can be pressed in one batch. Pressing shoes are motor-driven, and short-stroke hydraulic cylinders deliver fast, powerful pressing—perfect for efficient, high-capacity production.

Highlights:

- Straight, tappered or cambered glulam, columns, DUO and TRIO beams, blockhouse- and ceiling elements

-

Automated shape or camber setup

- Multiple layers per batch

- Stepped batches

- Motorized positioning

- Strong short stroke hydraulic pressing

- Automatic pressure control and readjustment

- Low consumption of energy

- Independent sectors for variable usage of press length

Advantages of short stroke hydraulic cylinders

- High power

-

Motorized prepositioning of pressing shoes

- Usage of full press width

- Short closing time

- Lower amount of hydraulic fluid