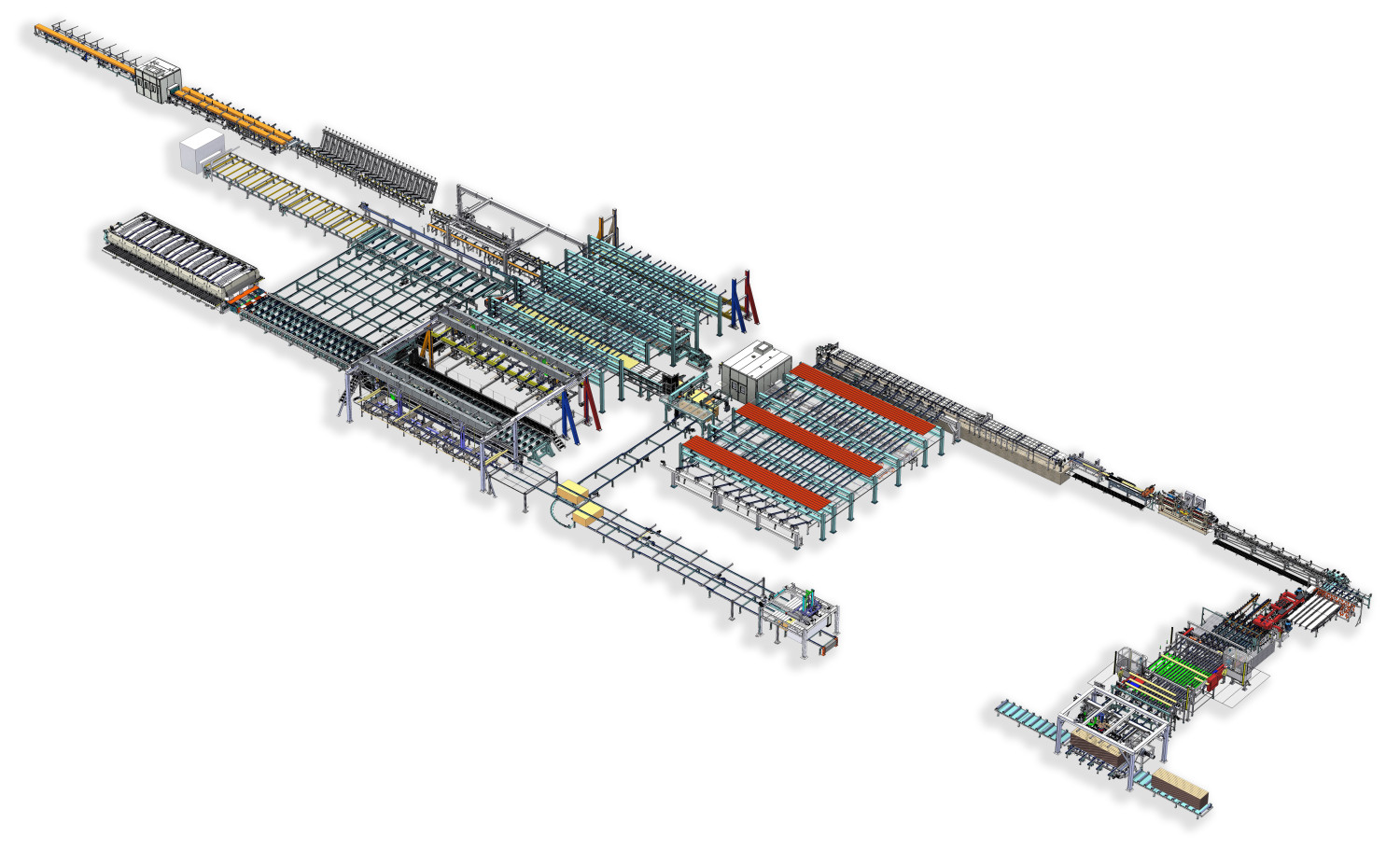

CLT production plant for Element 5 in Ontario Canada

Element5 has invested in a large-scale facility to expand its mass timber production capacity. The company’s new facility will produce CLT panels and glulam beams in a range of sizes, offering the market a versatile selection of mass timber products.

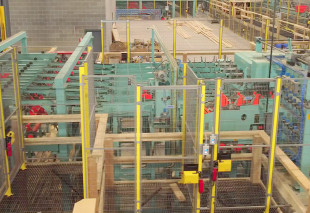

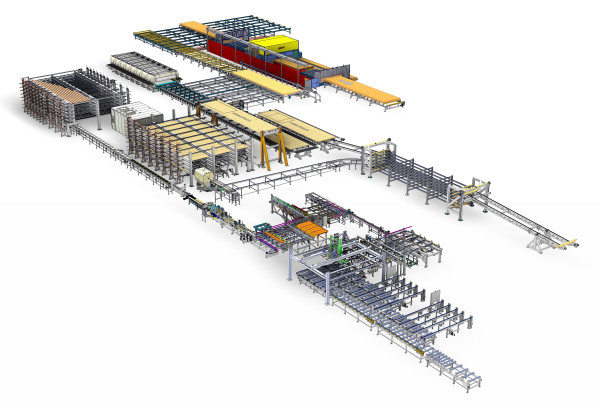

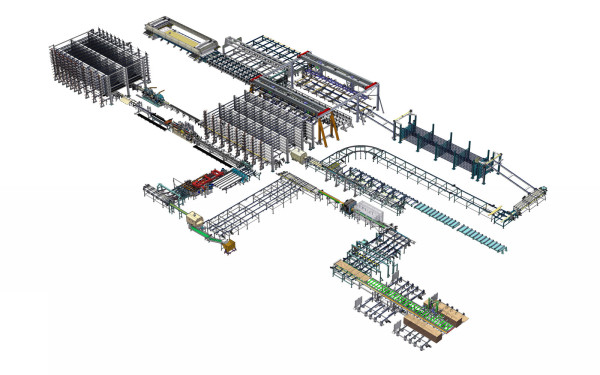

The production line is being installed in a new facility on a greenfield site strategically located at the midpoint between Toronto and Detroit. The line integrates the newly developed Z-Press to produce superior edge-glued panels. The maximum size of the CLT panels the factory will produce is 16 m x 3,5 m x 0,36 m. The panels have the option to be sanded on both sides for an enhanced visual finish. The facility also is equipped with wood conditioning capabilities and a state-of-the-art CNC router to machine the ready pressed and sanded CLT elements. This will be the first complete turnkey CLT line delivered to North America.

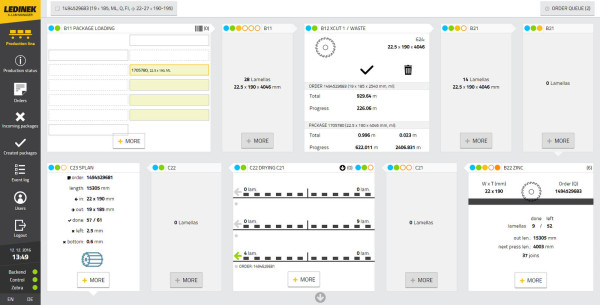

The entire line is integrated under the X-Lam Manager, a PC-based master computer system developed by Ledinek Engineering that provides production management, production flow control and visualization, statistics, real-time information and production analysis tools.

Company: Element 5

Location: Ontario / Canada

CEO: Patrick Poulin

Project Leader: Chris Latour

Employees: 50

Species: Spruce

Operators: 5+2

Production capacity: 40,000 m³ / y

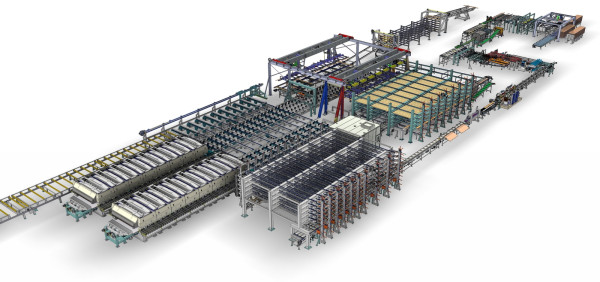

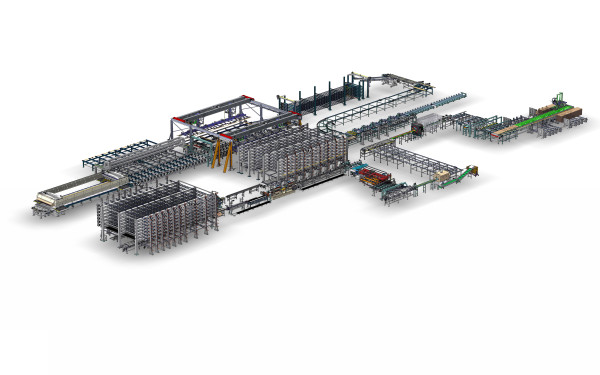

Turnkey CLT production

1. Vacuum de-stacking of 2 different timber qualities

2. Moisture meter with reject gate

3. Cross cut saws to remove timber defects at the board ends

4. Infeed system to finger jointing machine

5. KONTIZINK L-S120 finger jointing line with capacity up to 80 pcs/min; 120 m/min

6. Multi tray curing storage for the fresh finger joints

7. Infeed to the SUPERPLAN 4V-S350 planer for laminations, high speed and perfect finish

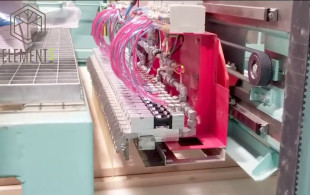

8. Hot-melt edge gluing Z-PRESS for fast assembly bonding of solid wood laminations.

9. Multi tray storage for longitudinal laminations

10. Cross-cut saw for cross lamination panels

11. Stacker for cross layer panels

12. Buffer for cross layer packages

13. Vacuum de-stacking for cross layers

14. Vacuum layer assembly unit for Longitudinal Layer

15. Vacuum layer assembly unit for Cross Layer

16. CNC controlled PUR (1 component polyurethane) glue application unit OEST

17. Solid fast movable PE coated aluminium table for CLT panel assembly

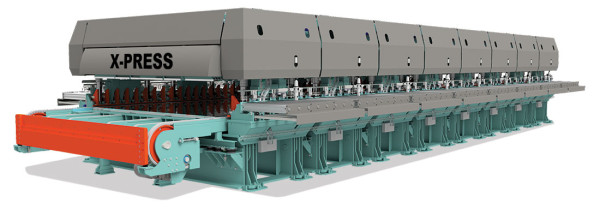

18. X-PRESS 16 - cross laminated timber press with up to 0,8 N/mm² pressure

19. X-PRESS 16 m x 3,5 m x 0,36 m

20. Longitudinal CLT panel push off unit with outfeed conveyor

21. Surface sanding machine IMEAS 3.200 mm wide

22. Glulam press up to 16 m long

23. EUROPLAN 600 4V beam planer 4 side + 4 chamfering units 600 x 300 mm

24. CNC joinery machine

Facts

- Up to 16 m x 3,5 m x 0,36 m panel size

- Production capacity up to 40.000 m³/year

- 80 m³ Shift production

- PUR glue used for higher capacity

- High flexibility of the CLT production process

- Totall installed power: app. 2.000 kW

- Dust extraction capacity app. 100.000 m³/h

- Recommended hall: 200 m x 44 m x 9 m