Sorting line for Sepa´s the existing finger jointing line!

Sepa adds an automated sorting line to the existing production

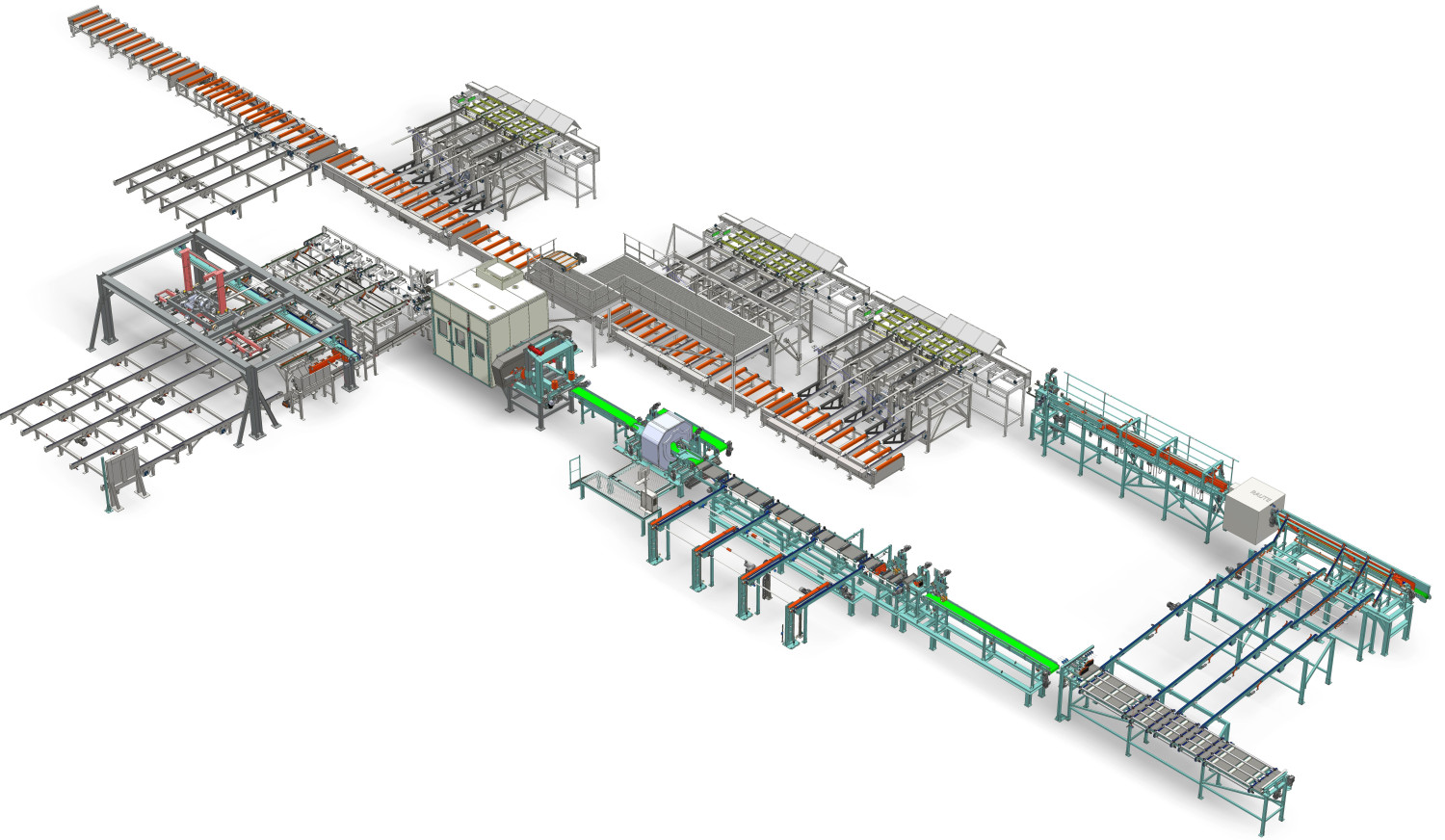

After the Finger jointing line installed in 2016, Sepa made another big investment. Replacing the existing old-fashioned, labour intense sorting, line with a new fully automated one.

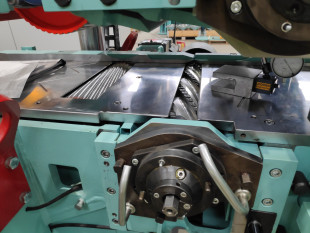

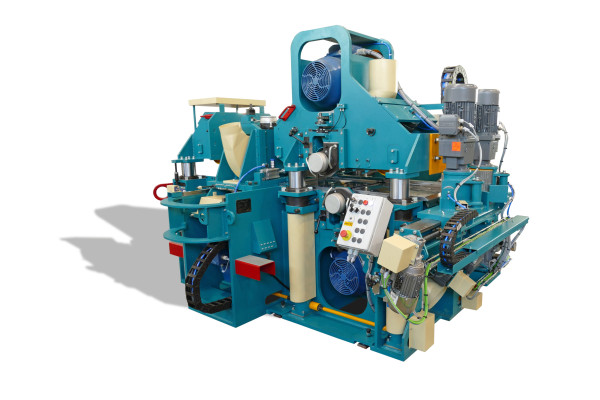

The new sorting line has a vacuum destacking and infeed system to the 400 mm wide planer. A bandsaw just behind the planer gives flexibility for different new products.

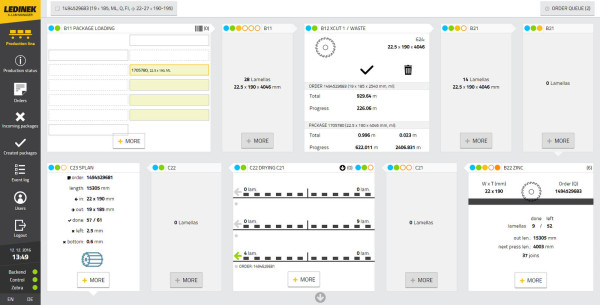

A scanner with AI learning network is checking for defects the customer has "learned" the machine to recognize. Together with the proof load bending machine, the line delivers

high strength timber for the following finger jointing process. Defects to be removed are marked by a line of luminescent ink, later detected by the X-Cut in the finger jointing line.

The line sorts to 3 grades C24, C30/35 and C45 also rejected boards. The 3 stackers put the packages on the roll conveyor to the strapping machine. After this packages are transferred directly to the finger jointing hall or to the external storage.

Company: Sepa Oy

www: SEPA OY

Location: Keitele / Finland

CEO: Esko Ovaskainen

Project leader: Aku Lindgren

Employees: 100

Timber species: Spruce, Pine

Production capacity: over 30.000 m³ / Year / 1 shift

Sorting line for the finger jointing line

- Cross chain conveyor for packages

- Vacuum destacking device

- Cup detection and turning station

- Infeed unit to the four-side planer

- Europlan 400 mm wide planer 120 m/min with horizontal bandsaw

- Horizontal spiral cutter block with carbide inserts

- Horizontal bandsaw – tiltable for splitting

- Smarti Scanner for defects with AI technology

- Aligning rollcase conveyor with side sweep lug chain

- Cross chain conveyor with layer backholders

- Outfeed of the proof load bending machine

- Aligning rollcase sorting conveyors with side sweep lug chains

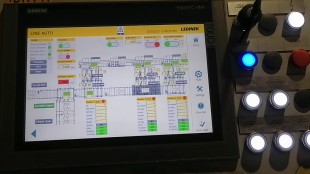

- iPlan Manager planing and sorting management system

- Printing station for grades and sizes

- Stacking machine

- Roller conveyor for sorted packages

Facts

- Board width 70 - 250 (400) mm

- Board thickness 20 - 80 mm

- Sorted to C24 up to C45

- Installed electrical power, approximately 260 kW

- Air volume for extraction 11.200 m³/h

- Fully automated planing and sorting process