Complete CLT production line for Schilliger Holz AG in France

The construction of wooden buildings is booming not only in Switzerland, but also in France and around the world. The demand for CLT large format panels has increased accordingly. In order to satisfy this demand in France and in the international export markets with domestic wood, Schilliger Holz AG is investing in an automated CLT production line in Volgelsheim.

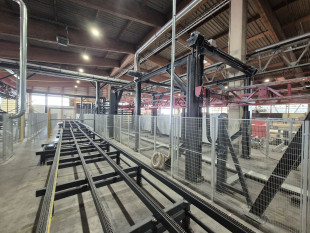

The order for the entire production line was placed with Ledinek. At the Volgelsheim location, the new production line will go into operation in the third quarter of 2023. The production capacity will be around 100 m³ per shift or 50,000 m³ / year in two-shift operation.

Decisive for the award to Ledinek was the many years of experience with CLT systems. Thanks to its extensive machine portfolio, Ledinek is really the only full-range supplier in this area. This avoids unnecessary or problematic interfaces by default.

When selecting the supplier for the CLT line, the owner-managed family company relies on the latest findings and technical standards.

"We were won over by the performance of individual main machines, the innovative approach and the coherent system concept," says owner and managing director Ernest Schilliger.

Ledinek will also implement new concepts with this system that are unique to date. This is achieved by further developing the existing machines. However, more information will only be given after commissioning.

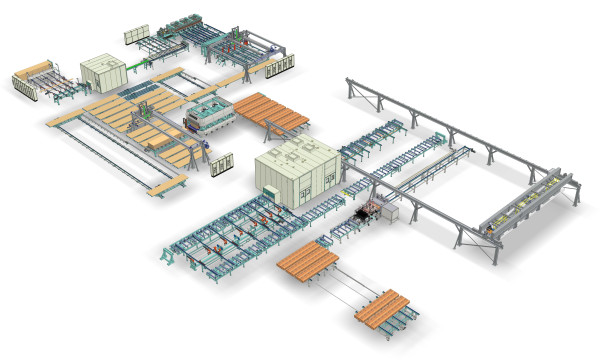

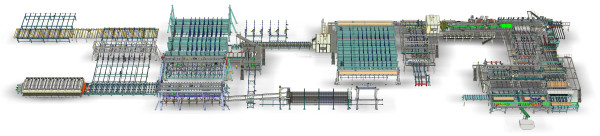

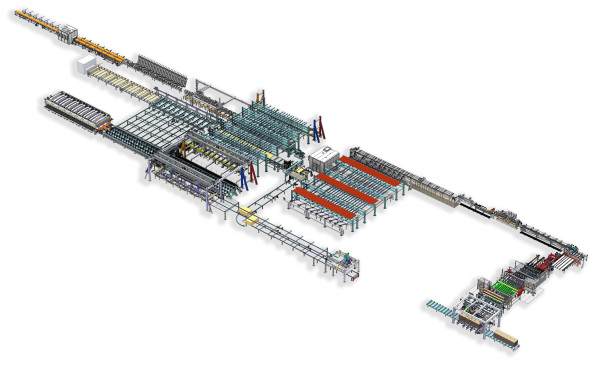

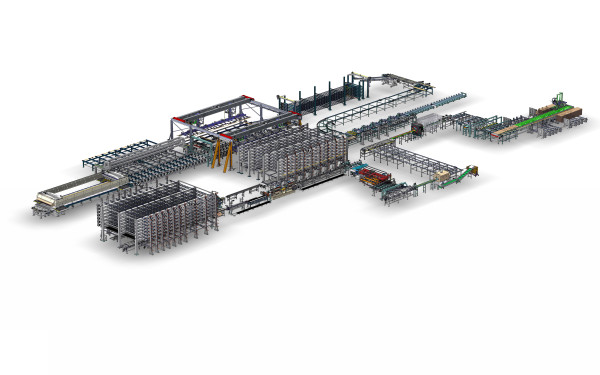

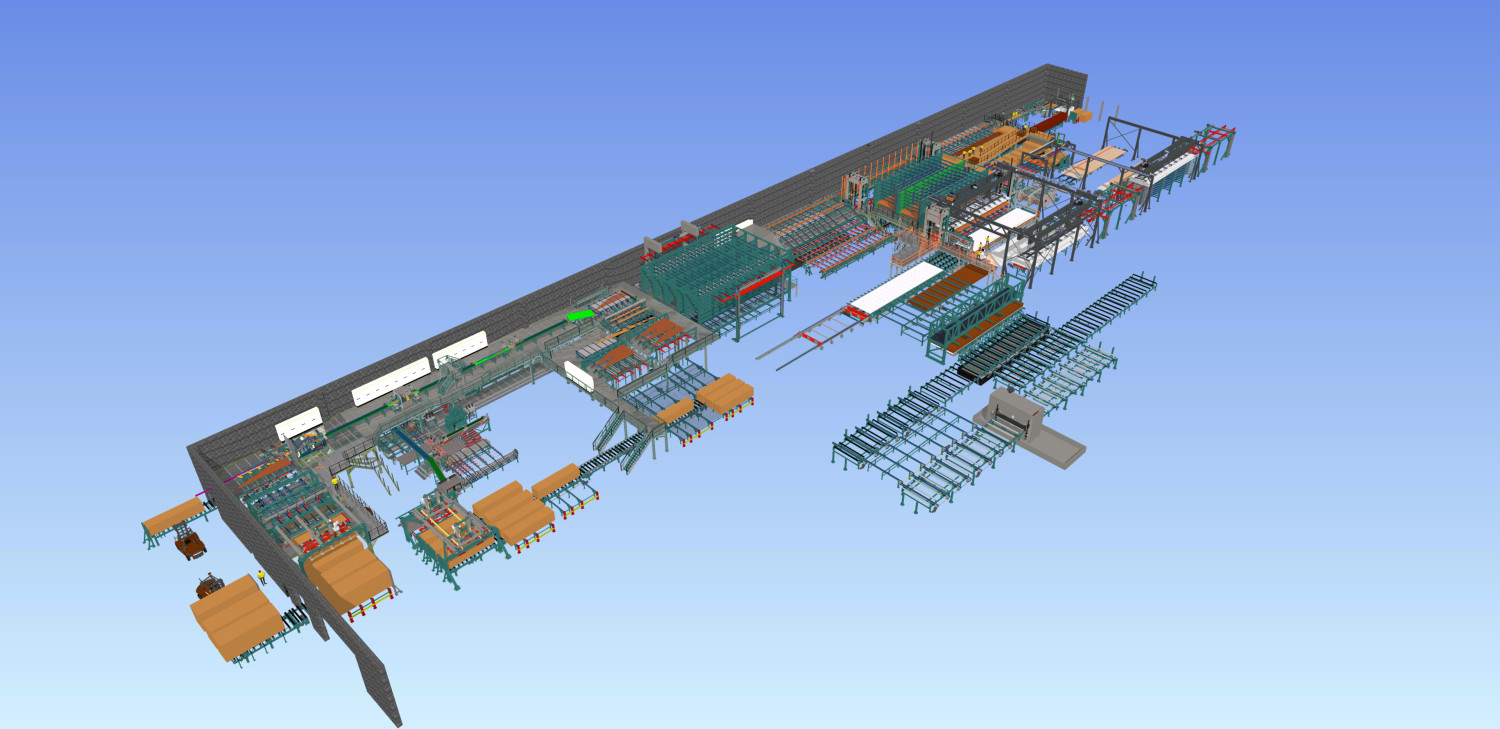

The line consists of a quality sorting system with a planer and scanner, as well as 2 stacking machines for different qualities. The goods prepared in this way can be supplied to CLT production either directly or via the warehouse.

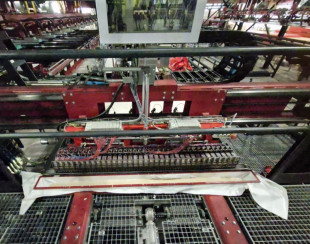

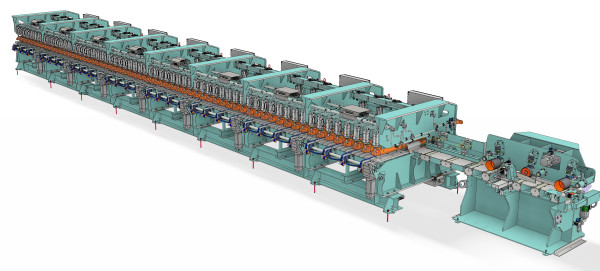

Fast vacuum destacking, the X-Cut cross-cut saw and the powerful Kontizink 2500 finger-jointing cycle system deliver up to 20,000 lm of lamellas per shift. This is followed by a generously dimensioned curing warehouse, a SUPERPLAN S400 lamella planer and the innovative Z-Press 16 joint gluing system for the production of pre-glued single-layer panels for lengthways layers.

The transverse layers are supplied by a Z-Press CL which, through external tasks, allows the system's performance to be increased further. Large plate buffers for lengthways and crosswise layers give the system the flexibility it needs to be able to produce batch size 1 without any loss of performance. After the 26-fold review of the X-Press 16, it goes to the grinding machine and on to the CNC-s. Due to its flexibility, the line is also designed for the production of KVH.

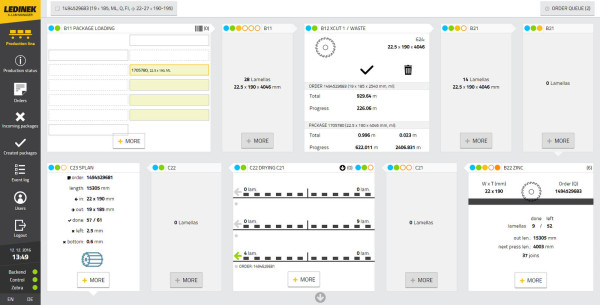

The entire system is controlled by the master computer "X-Lam Manager", which exchanges data with the in-house ERP.

Company: Schilliger Bois

www: Schilliger

Location: Volgelsheim / France

Project Leader: Schilliger

Production Manager: Hélène Desjardins

Employees: 110 employees

Species: Spruce

Operators: 10 per shift

Production capacity: 50.000 m³ / year

Turnkey CLT production

- Package intake, vacuum de-stacking, loading into the measuring chain

- Moisture control and cup detection with turning device

- Pre-planer Superplan 4V-S350

- Microtec scanner

- Quality marking and cutmark station

- Package stacker for sorted board in quality

- Infeed finger jointing line

- Cross cut saw X-cut for defect marked boards

- KONTIZINK 2500 with PUR finger joint glue application

- Curing deck with 6 levels, each level divided into two sections

- Spare lamella storage

- Superplan 4V+4F S350 lamella planer

- X-cut saw for KVH length cut

- Finger jointed boards / KVH stacker and outfeed

- Hot-melt and PUR edge gluing Super Z-PRESS 16 for fast assembly bonding of laminations and optional structural bond

- Elevators for single layer panels in full width

- Multi tray storage for edge bonded longitudinal single layer panels

- Hot-melt and PUR edge gluing Super Z-PRESS CL for fast assembly bonding of laminations and optional structural bond

- Elevators for single layer panels in full width

- Multi tray storage for edge-glued cross lamination layers

- 2 Vacuum layer assembly units (separated for longitudinal and cross layers)

- PUR (1K Polyurethane adhesive) surface gluing

- X-PRESS 16 - cross laminated timber press with up to 0,8 N/mm² pressure

- CLT panel push off unit (crosswise) with chain and roll conveyors

- ID Label printer for raw billet identification

- Wide belt Sander with bypass

- Turning station for quality inspection

- Roll and chain conveyors before CNC machines

Facts

- Up to 16 m x 3,6 m x 0,50 m panel size

- Production capacity up to 50.000 m³/year

- Up to 100 m³ Shift production

- Z-Press Super for edge gluing with hotmelt and PUR glue

- PUR glue used on the surface for higher capacity

- High flexibility of the CLT production process