Arboreal: the only Mass Timber Plant in Uruguay

and one of the largest in Latin America.

The introduction of the Arboreal project in Uruguay marks a significant milestone in the construction and environmental sectors of Latin America. As of early 2022, Uruguay is home to the region's first large mass timber factory, following strategic acquisition and expansion efforts led by U.S. businessman Mark Crandall and Uruguayan entrepreneur Matias Abergo. The project began with the acquisition of the largest pine sawmill of Uruguay, located in Tacuarembó, northern Uruguay, with a production of 240,000 m³. The feedstock used by Arboreal is 100% FSC, obtained from local Southern Yellow Pine plantations. Arboreal is committed to establishing a sustainable timber industry in Uruguay.

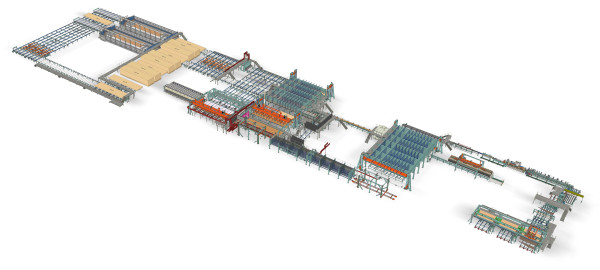

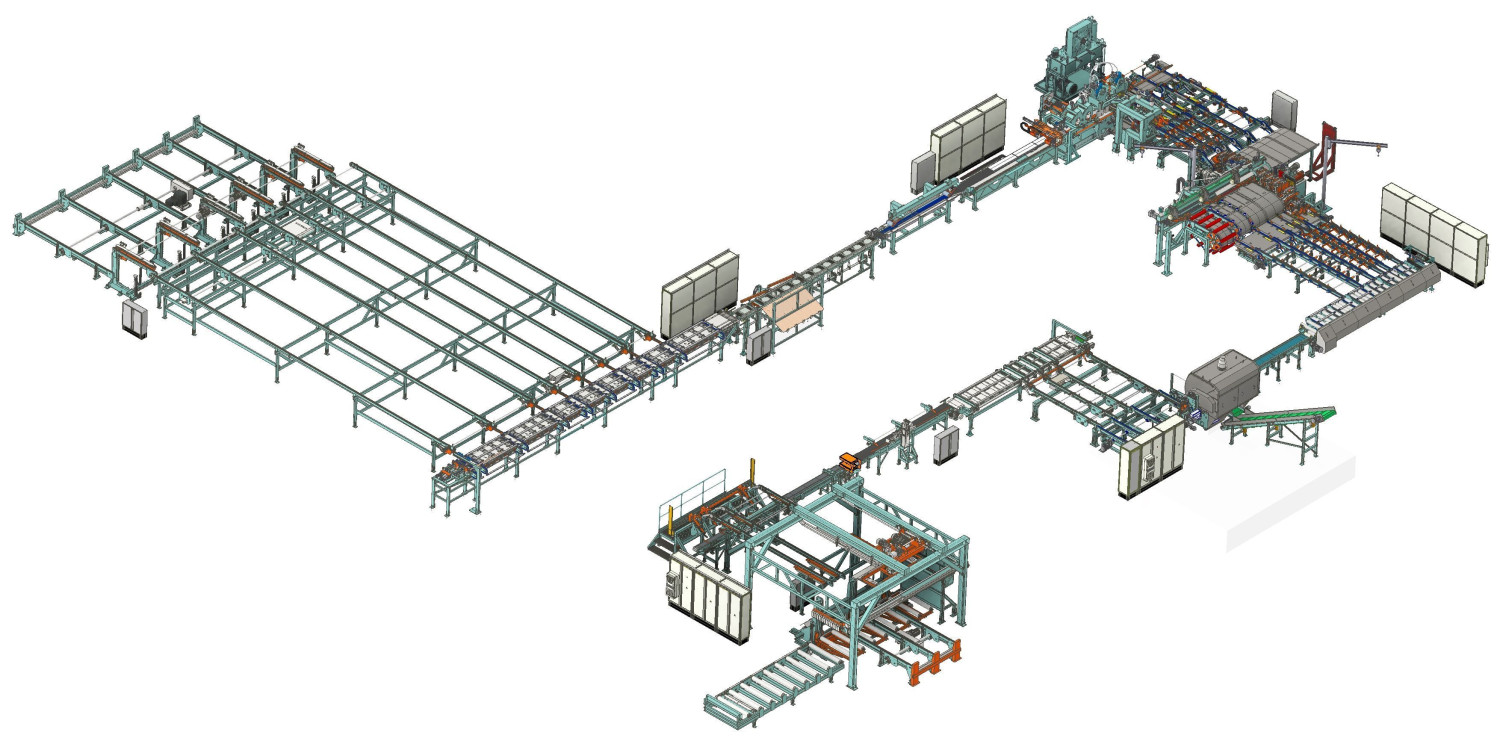

The mass timber plant, which is touted as the largest and most advanced of its kind in Latin America, began its operations with a production capacity of 50,000 m³ per year. In Tacuarembó, the factory manufactures structural finger-jointed solid timber, cross-laminated timber (CLT), and glued laminated timber factory, with the goal of being a world-class supplier of construction elements and building projects. Therefore, Arboreal has established a Technical Office in Montevideo, responsible for the design and engineering of the timber projects, in an integrated workflow aligned with global efforts to combat climate change. According to Matías Abergo, President of Arboreal, the utilization of mass timber for construction is pivotal in reducing CO2 emissions. The construction sector, which is responsible for nearly 40% of global greenhouse gas emissions, can significantly benefit from the carbon sequestering capabilities of mass timber structures.

Choosing Ledinek as the supplier for its mass timber manufacturing line was a strategic decision for Arboreal, emphasizing the necessity for experience and reliability in pioneering such a significant project. Ledinek's reputation for delivering state-of-the-art machinery ensures that the plant's operations are both efficient and up to global standards.

This initiative not only positions Uruguay as a leader in the mass timber market but also promotes sustainable development of wood construction, boosting local industries and environmental sustainability. The Arboreal plant serves as a model for future developments in eco-friendly industrial practices and building in Latin America and beyond.

Company: Arboreal SA

LinkedIn: Arboreal

Production site: Tacuarembó/ Uruguay

Technical and Commercial Office: Montevideo, Uruguay

President: Matias Abergo

General Manager: Craig Penfold

Production staff: 20

Wood species: Southen Yellow Pine (Pinus taeda and P. elliottii)

Production capacity: 50.000 m³ / Year

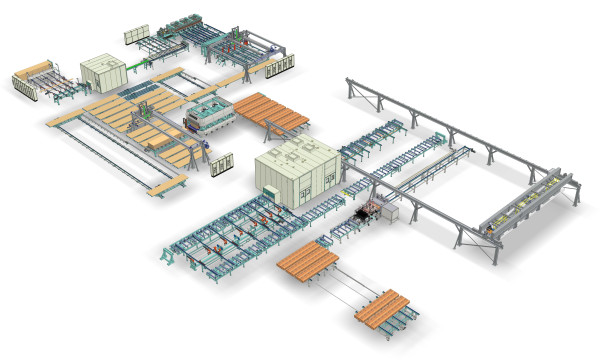

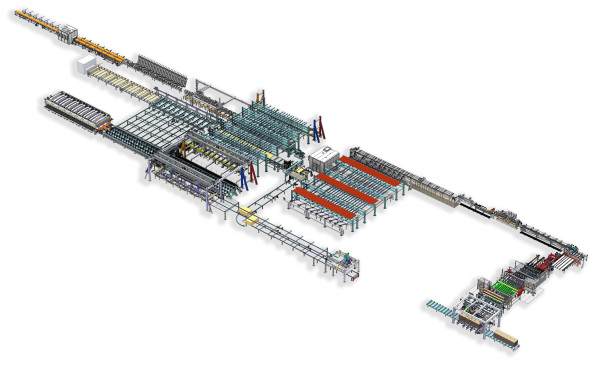

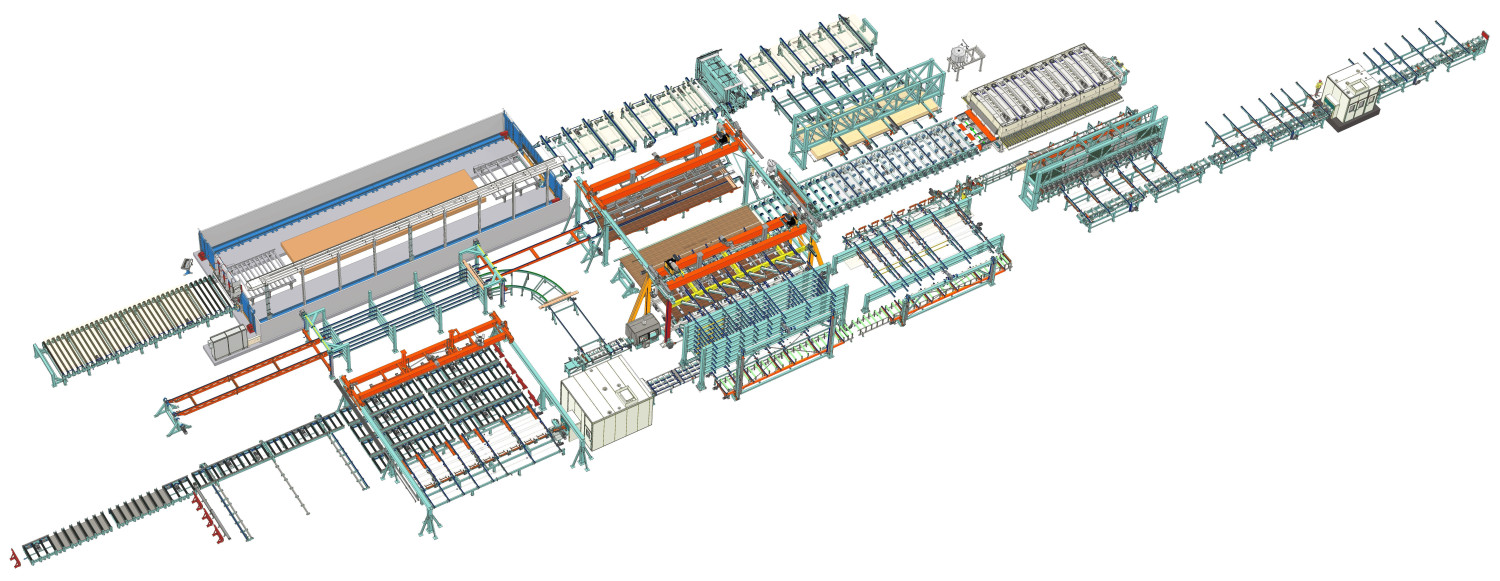

CLT and GLT production combo

- Vacuum destacking device for packages

- Marking station with flip unit for boards

- Reading station for cut marks and moisture meter

- X-CUT S400L defect cutting saw

- KONTIZINK 2000 finger jointer machine

- Rollcase conveyor with side sweep lug chain

- PUR glue curing storage 15 m

- Stacking machine for finger jointed laminations

- Roll Conveyor for 4 packages with shuttle and vacuum destacking to planer

- MULTIPLAN 4V-S200 all-side planer for laminations

- X-CUT S200 with Infeed for cross lamella cutting

- 3 story storage with back holder for short laminations

- 5 level storage for longitudinal layers

- Vacuum stacking machine for preparation of layers before pressing

- X-Press 12 Cross timber press

- Rake off station for CLT Panels with lifting device

- 2 level glulam lamella storage with singling

- Maxipress 1000-12 for standard glulam

- Europlan 600-4V+4F S60 beam planer up to 600 x 300 mm

- Sanding machine for CLT

Facts

- Up to 12 m x 3,5 m x 0,35 m panel size

- Production capacity up to 50.000 m³/year

- 100 m³ Shift production

- PUR 1K glue with cold setting

- High flexibility of the CLT production process