High-performance plant for CLT production at Mayer Melnhof in Leoben

State-of-the-art machinery combined with know-how convinces Mayer Melnhof once again

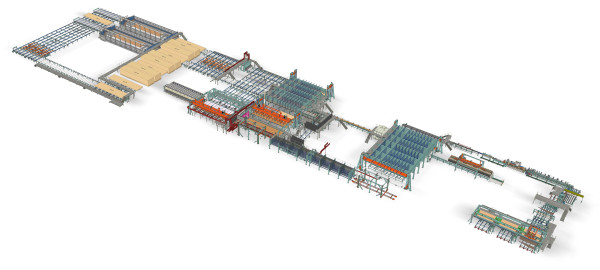

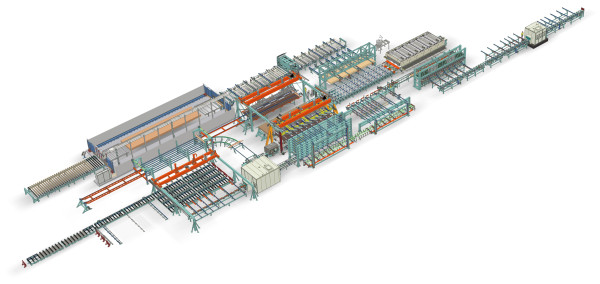

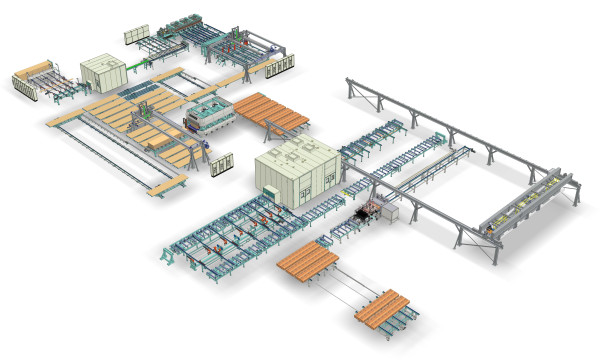

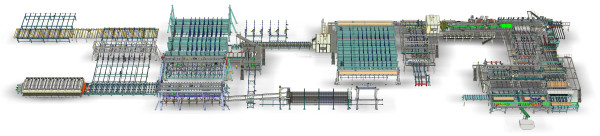

The new cross laminated timber plant of Mayr-Melnhof Holz in Leoben is a prime example of modern wood processing and automation at the highest level. This project, one of the largest of its kind in the world, was completed in just two years - from the ground-breaking ceremony to the production of the first CLT panel. With an area of over 3 hectares and an investment of 175 million euros in the first expansion phase, the plant represents a significant step forward in the production of high-quality cross laminated timber, with a planned annual capacity of up to 130,000 m³.

Ledinek is the main supplier for the entire spectrum of wood processing, from the raw lamella to the finished panel. The company has used its extensive experience in the realization of glulam lines to implement the largest single order in its history to date. Despite the enormous size and complexity of the project, Ledinek succeeded in meeting the high performance requirements of Mayr-Melnhof Holz through meticulous planning and the development of sophisticated detailed solutions.

The production line begins in the planing mill, where a high-performance Stratoplan 6VR-S1000 planing machine ensures the necessary throughput. From there, the planed timber packages are transferred to the cross laminated timber plant and automatically transported to the buffer and destacking stations by an ingenious shuttle system. The Kontizink 2500 finger-jointing lines, of which two are already in operation and space is planned for a third, guarantee the required output for processing the boards into lamellas for the longitudinal and transverse layers.

After finger-jointing, the lamellas are temporarily stored in an extensive multi-level storage system and efficiently handled by advanced lift systems. Final processing takes place in two third-generation X-Press presses, which can produce panels up to 16 meters long and 3.5 meters wide. The specific pressing pressure can reach a maximum of 0.8 N/mm² at full width.

Despite delivery difficulties for individual components due to the pandemic, the large-scale project was completed without any significant delays. The successful commissioning and compliance with the agreed performance figures underline the strong partnership and high level of commitment of both teams. This cooperation has not only led to the successful completion of the plant, but also to a further strengthening of the long-standing relationship between Ledinek and Mayr-Melnhof Holz.

The CLT plant in Leoben is therefore not only a technological highlight, but also an example of the successful implementation of a visionary project through perfect cooperation between customer and supplier. With this plant, Mayr-Melnhof Holz is setting new standards in the wood industry and strengthening its position as one of Europe's leading wood processors.

Company: Mayr-Melnhof Holz Leoben GmbH

Location: Leoben / Austria

Overall project manager: Manuel Staber

Operations manager cross laminated timber plant: Markus Thier

Production manager cross laminated timber plant: Martin Klingenbrunner

Cross laminated timber plant employees: 50

Type of wood: Spruce

Operators: 6 per shift

Production capacity: 130,000 m³ / year in full operation

Mega CLT production

- Package shuttle and day storage for timber packages

- Vacuum destacking system for 4 qualities

- X-CUT S400 high-performance cross-cut saw with infeed

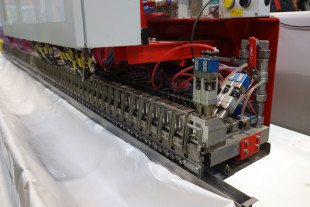

- KONTIZINK 2500 single board finger jointing line from the KONTIZINK machine line

- Curing store 8 levels with lifting conveyor

- SUPERPLAN 4V-S350 four-sided planing machine with infeed

- Z-Press 16 m edge gluing system with hot-melt adhesive for assembly bonding

- Longitudinal layer buffer - 6 decks, 2 drive sections

- Lifting conveyor for longitudinal layer panels

- Longitudinal layer preparation station (pick up, align)

- Vacuum stacking device for longitudinal laying before surface pressing

- CLCS 1.600 cross layer cut saw

- Turntable with mounted chain cross conveyor - 90° rotation

- Cross-layer buffer - 15 levels, 30 panels in total

- Vacuum stacking device for cross layer placement

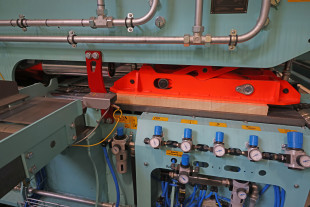

- PUR application system Oest - 3500 - CNC

- X-Press 16 press specially developed for high end CLT production

- Cross pusher for CLT elements with lifting table

- Turning station for CLT elements

- Calibration sanding machine

Facts

- Up to 16 m x 3.6 m x 0.36 m panel size

- Production capacity over 130,000 m³/year

- Over 200 m³ shift production

- Z-Press 16 for faster and safer operation

- PUR adhesive for higher capacity

- High flexibility of the CLT production process