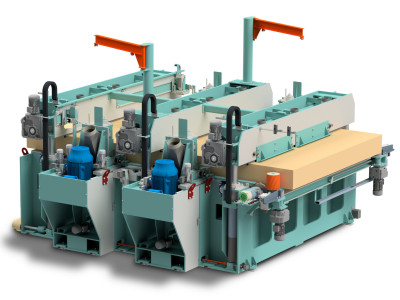

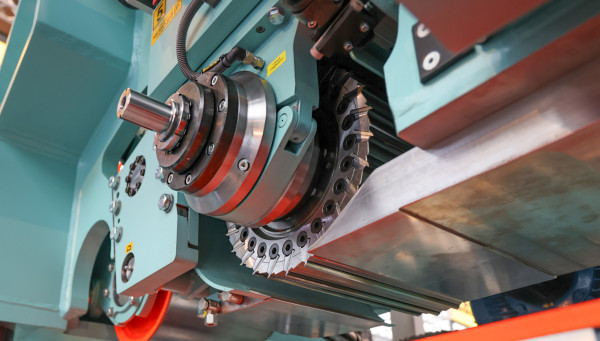

Planing Profiling

A full range of industrial moulders and planers. Enhanced with innovative ideas.

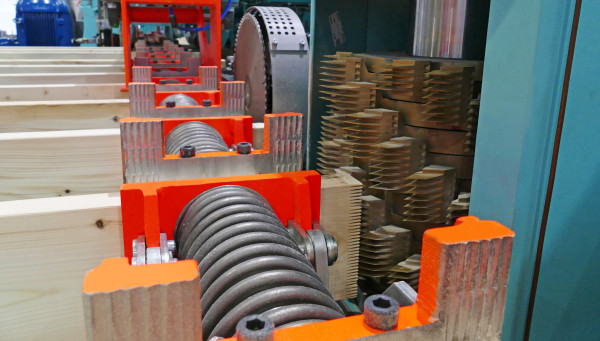

Finger jointing

Finger jointing machines and lines are a masterpiece of the woodworking industry

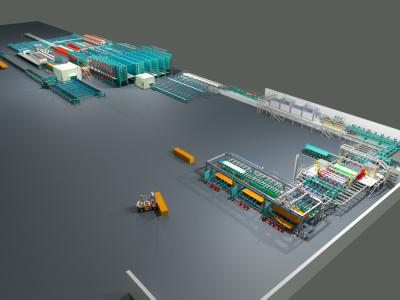

Engineered Timber

Strong and innovative pressing solutions for glulam and cross laminated timber CLT products