Rotoplast

100% calibrated

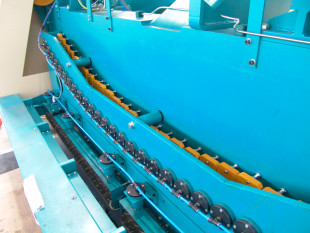

A front face milling process for machining the surface of plastic sheets and plastic elements. If you are looking for a perfectly planed surface in your production process, then there is no better solution as the ROTOPLAST system. It guarantees a 100% calibration of the workpiece and a perfectly flat plane surface without cutter waves. Machines are available in many different widths, suitable for every application, even for workpieces up to 2,7 m in width.

ROTOPLAST can be adapted for the most unusual request, even beyond the common list of options and materials. For this, we put our reputation at stake.

Highlights:

- Surface calibrating machine for plastic

- Absolutely precise bearings

- Carbide or diamond tipped inserts

- Tooling segments for faster exchange

- Honing pin for equalizing of carbide inserts

- Variable frequency drive for continuous adjustment of rotor RpM

Materials:

Polyethylene (PE, HDPE, LDPE, UHMWPE,…), Polypropylene (PP), Polyamide (PA), Polycarbonate (PC), Polyoxymethylene (POM), Poly(methyl methacrylate) (PMMA), Phenol formaldehyde resin (PF), Polyvinyl chloride (PVC), Polystyrene (PS, HIPS), Polytetrafluoroethylene (PTFE), Polybutylene terephthalate (PBT), Polyvinylidene fluoride (PVDF), Acrylonitrile butadiene styrene (ABS), Ethylene chlorotrifluoroethylene (ECTFE), Polysulfone (PSU), Polyurethane (PUR, TPU), Polyether ether ketone (PEEK), Polyimide (PI)